Administration¶

The following section describes the administration features and configuration setup within ShipHawk WMS.

Administration Options¶

ShipHawk WMS provides a comprehensive set of administration features to:

- View Order Status Summary

- Reprint documents

- Reprint labels

- Regenerate documents

- Regenerate labels

- Regenerate EDI

- Reset orders

- Reset Entire Batch

- Cancel orders

- Edit addresses

- Edit other key order attributes

- Set Order to Unreleased Status

- Request VICS Bill of Lading (BOL)

- Request Commercial Invoice (CI)

- Confirm All Remaining Picks

- Confirm Individual Picks Manually

- Request Freight Quote

- Request Freight Quote Status

- Assign Task(s) to Employee

- Request Global-e Manifest

- Request BorderLinx Manifest

- Request Passport Manifest

- Check Security Protocol

- Display Negative Inventory

- Change Your Password

- Manage User Credentials

- Manage Workstations

Operations & Usage¶

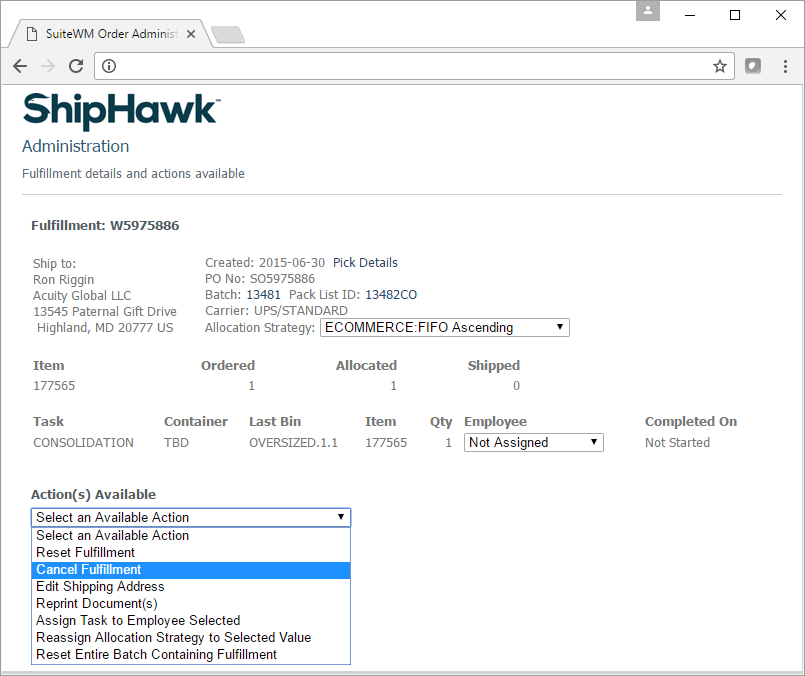

ShipHawk WMS delivers all administration options using a very simple approach that prompts an operator to enter either a fulfillment (order), batch pick ID, container ID, purchase order, or item (for item history), and then presents an array of options/action that can be taken on that order based on its current status. This is highly dynamic process that takes a potentially complex process and makes it very simple for the operator.

Tip

This feature is a very effective “one-stop-shop” for all information (and history) relating to an order, and should be the first place to begin any customer service research relating to an order.

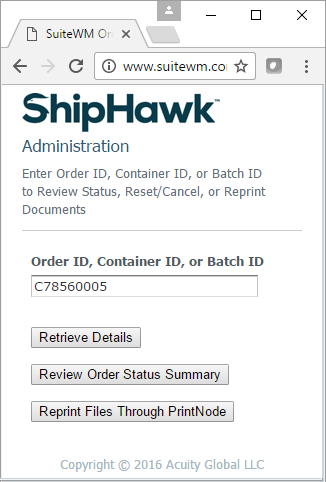

For example, an operator enters a container ID in the Administration page shown below:

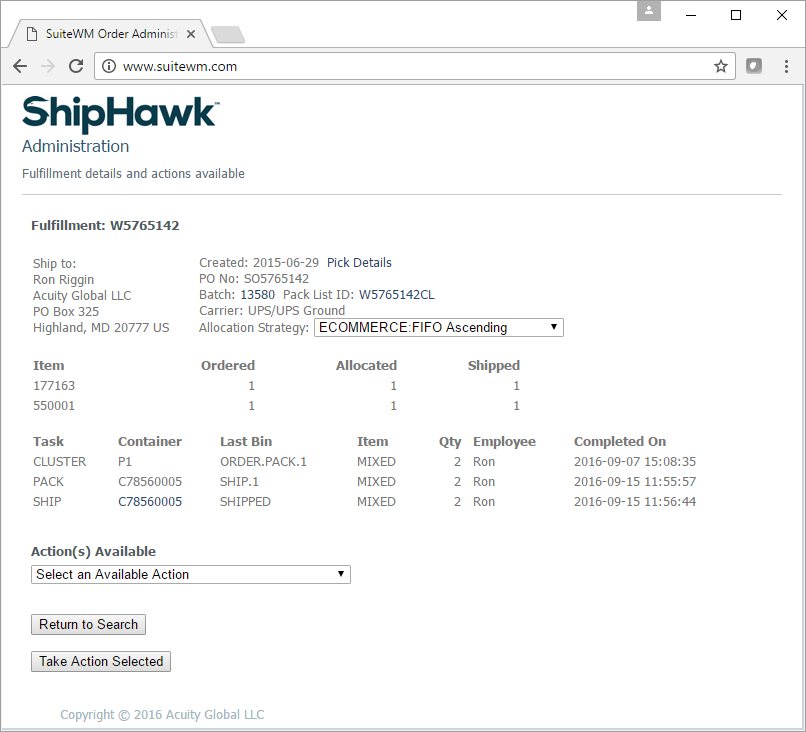

ShipHawk WMS locates that order based on the container, order , or batch ID scanned and presents all of the information that is known about that order.

If the order is shipped, the operator can simply select the shipped container and ShipHawk WMS will present a detailed view of all attributes related to that specific container.

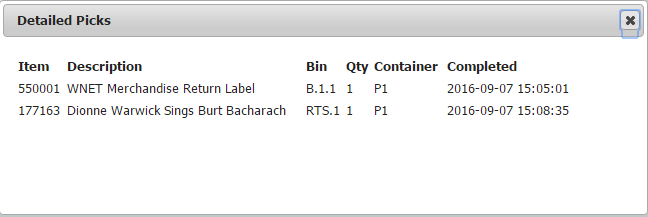

Specific picks for this container can be easily reviewed by clicking Picking Details on this page

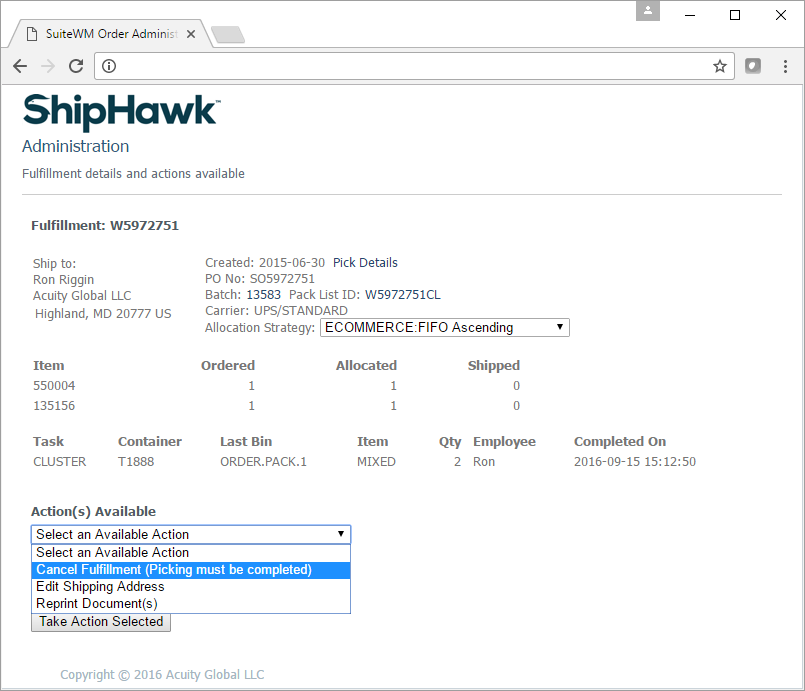

Numerous Administrative options can be invoked by selecting from the Drop Down and clicking Take Selected Action. The option shown vary with the state of the order. In this example below, the options are shown for an order that has already been shipped.

The Batch details for any order can also be reviewed by clicking the Batch link

A comprehensive Order Status Summary page is also available in ShipHawk WMS under the Administration Page. This option displays a summary of orders in different statues, from release-not-picked, picked-not-packed, packed-not-shipped, and shipped-today. An example of this page is shown below. Any order can be easily accessed with single click, which delivers the operator to the Order Summary page shown above.

Reprinting Documents¶

This Action will reprint any documents previously created. It does NOT regenerate the document; rather it retrieves the previously created PDF and directs that specific file to the printer. This is useful if a hardware-based printing problem is encountered.

Reprinting Labels¶

This Action is the same as reprinting documents, except that it is specific to labels such as ship labels. This will retrieve any previously created ZPL-based labels and direct them to the printer. Like reprinting documents, this is useful if a hardware-based printing problem is encountered.

Regenerating Documents & Labels¶

If a document or label needs to be regenerated because a condition or data has been changed since the original document was printed, this is the Action that should be selected by the operator. This action will initiate the necessary ShipHawk WMS processes to regenerate the requested document or label. If a shipping label is to be regenerated, it will create a new tracking ID for the package.

Resetting Orders¶

This Action can only be performed if picking has not yet begun. Resetting an order will remove the order from any wave and batch. It will also deallocate any inventory and places the order in the initial state it was received in from the ERP.

Canceling Orders¶

Order cancellation is always a challenge in the warehouse, especially if picking has begun on the order. This Action, however, keeps the process very simple to manage, even after picking has begun. In fact, unless you have shipped the order, ShipHawk WMS will allow you to cancel a fulfillment order, and manage the re-slotting of any picked inventory without the need to perform any inventory adjustments or re-receipt of the inventory.

To begin, the authorized operator would access the Administration Menu and enter the order number or scan one of the containers on the order. The page is shown below. Based on the status of the order, ShipHawk WMS will list a variety of valid actions to take for this order. In this case, the order has begun picking, so an option to cancel is order is shown.

Of course, if picking has not yet begun, the operator can also cancel the order as shown on the page below.

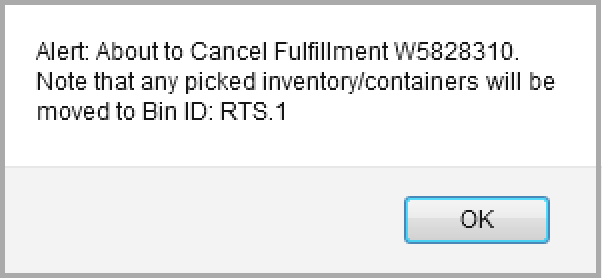

Once the “Action to Take” is selected, the operator will be sequenced through a series of validation steps (to confirm the action requested). Once confirmed, the order will be canceled in ShipHawk WMS. The inventory and containers will be automatically moved to a specifically designated bin or staging area for “return to stock” (or RTS) inventory, as is shown below.

This “return to stock” bin may be defined as an allocatable bin, or not. If allocatable, then inventory in this bin is considered available for allocation and pickers could be directed to that bin if the allocation strategy dictates this. If not allocatable, then no picks will ever be allocated to that RTS bin, and you will need to move the inventory out of the bin to an allocatable bin.

To move inventory from the RTS bin, the operator will use the standard Move features to identify the Bin, Item, Quantity to Move. The operator may also simply scan the Container ID on the inventory to initiate a move. The operator can then select the standard “Suggest Bin” option and ShipHawk WMS will direct the operator to the proper bin based on the standard putaway rules setup for this item (see Putaway).

Editing Order Addresses/Attributes¶

At times, data received from the ERP on the order must be changed at the last minute in the warehouse. This Action permits that, allowing authorized operators to edit order attributes at any time, but before the order is shipped.

Configuration Setup¶

List of Values (LOV)¶

ShipHawk WMS business processes are driven by rules and settings defined by the user. While much of this data is standard to NetSuite, rules and setting specific to ShipHawk WMS are defined in a simple custom table named ShipHawk WMS List of Values. The sections below define the usage of this tables and typical values for each business process type.

Attention

Please note that caution should be taken when adding, updating or deleting any of the values noted below since they are all acted upon in real time by ShipHawk WMS. Please conduct appropriate testing of each value set in a Sandbox environment before migrating any new or revised settings to a Production environment.

Rules¶

Usage:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 |

|---|---|---|---|---|

| RULE | Description of the rule | Specific Code not to be changed | Value for this rule | Secondary Value |

| Rule Name (LOV Code) | Description of Rule | |

|---|---|---|

| Enable Respose Time Audit (enableresposetimeaudit) | This setting uses the logging process to record the start and end of a transaction response time in the database. The event is recorded by a timer with checkpoints and timestamps that is added programmatically to your environment. Rule is set to ‘FALSE’ by default. | |

| Enable Scan Pack Countdown Duing Inspection (enablescanpackcountdownduinginspection) | This setting implements the scan-pack countdown during the inspect container process. The scan-pack countdown removes an item from the list when an operator scans it for packing. This process also alerts the operator when all items in a container have been scanned. Rule is set to ‘TRUE’ by default. | |

| Use ERP-defined SSCC Pack Attributes (useerpdefinedssccpackattributes) | This setting will use the pack attributes defined in NetSuite by default instead of the attributes defined in ShipHawk WMS. Rule is set to ‘FALSE’ by default. | |

| USPS Media Mail | This setting adds UPS Media Mail as a shipping service. | |

| Enable Hub Address on BOL (enablehubaddressonbol) | This rule applies orders consolidated on the BOL. This setting overrides the ‘Ship To’ address on the BOL to match with customer records from the Address Table. The Address Table contains an element that stores the hub. Rule is set to ‘TRUE’ by default. | |

| Enable HMAC-SHA256 Signature Method (sha256) | This setting uses HMAC - SHA256 as an authentication code that uses hashings for security. If not set, the authentication method will default to HMAC-SH1. Note: HMAC-SHA1 is deprecated as of NS 2021.2 Rule is set to ‘TRUE’ by default. | |

| Enable SCAC Lookup (enablescaclookup) | This setting adds an SCAC lookup option to the Source Data Maintenance page. A SCAC is a unique code used to identify carriers. Rule is set to ‘FALSE’ by default. | |

| Default Container Type (defaultcontainertype) | This rule sets a default container type that is used upon weighing. This rule is used with “Pack Add” (under the Pack/Inspect option in ShipHawk WMS) only. The Container Type is set to 12x12x12’ by default. | |

| Enable Order Hold Code (enableorderholdcode) | This setting will place an order hold when a value is specified in the ‘salesorder.so_hold_code’ element. When an order hold is placed, allocation in wave and fulfillment processing cannot occur Rule is set to ‘FALSE’ by default. | |

| Disable BOL Handling Units (disablebolhandlingunits) | This setting will disable the ‘Handling Units & Packages’ display on the BOL, leaving the field blank. This means you will be able to manually write in values for this field instead. This is a solution for users who have specific cartons and pallets that are not defined in ShipHawk WMS. Rule is set to ‘FALSE’ by default. | |

| Use Customer PO Number on BOL (usecustomerponumberonbol) | This setting fills in the Customer PO Number in the ‘Customer Order No’ section on the BOL. This differs from the default, in which the ShipHawk WMS Order No is used instead. Rule is set to ‘FALSE’ by default. | |

| Print Copies of BOL (bolcopies) | The default number of copies printed of the BOL. Rule is set to print ‘1’ copy by default. | |

| Include Pallet Tare Weight on BOL (includepallettareweightonbol) | This setting will add a TARE weight line on the BOL. When a value is entered for the TARE weight, this value is multiplied by the number of pallets created for the shipment. The weight of a typical pallet should be entered in ShipHawk WMS when using this setting. Note: An empty value will not alter the BOL. Typical Pallet Weight is set to ‘40’ by default. | |

| SPS Bearer Token and Expiration (spsbearertoken) | This setting stores the SPS bearer token and its related expiration date/time when it is retrieved via the SPS API. It is important that the value of the token persists, as only 10 API calls to the SPS token are permitted per hour. The token is stored as a JSON string. | |

| Alter Table customer Add Column cust_label_v2_id | Add element to store the SPS Retail Label V2 ID, this element is used when rule (enablespsv2) is ‘TRUE’. | |

| Alter Table archivesalesorder Add Column so_confirm_date datetime | Add column to the archivesalesorder table to record the date/time confirmation of the sales order | |

| CSV 940 API Create Shipments (csv1apicreateshipments) | Enable this setting to create shipments from sales orders using the 940 CSV API. Rule is set to ‘FALSE’ by default. | |

| Allocate Orders on Hold allocateordersonhold) | Enable this setting to allocate all orders that have been placed on hold, and hold them in the’Wave Unreleased’ tab. Rule is set to ‘FALSE’ by default. | |

| Remove Cancelled Order from Database (removecancelledorderfromdatabase) | If this setting is enabled, a cancelled order will be removed from the ShipHawk WMS database. This differs from the default configuration in which a rule is marked as ‘cancelled’ but still remains in the database for record keeping purposes. Note: This Rule must be set to ‘TRUE’ if your ERP system will send new orders with the same Sales Order number as a cancelled order. Rule is set to ‘FALSE’ by default. | |

| Display Packing Messages at Shipping (displaypackingmessagesatshipping) | This setting will present packing messages to operators during the shipping process. Packing messages are intended to assist operators in preparing containers/packages for shipment. Rule is set to ‘FALSE’ by default. | |

| Inbound ASN Version Enabled (inboundasnversionenabled) | Specify whether your account manages Inbound ASNs. If this setting is enabled, ShipHawk WMS will accept and manage Inbound ASNs (which are then mirrored as Inbound Shipments in NetSuite). There are three options to select from: 0 - feature not used 1 - initial version deployed 2 - newest version deployed, for all new customers Rule is set to 0 by default. | |

| Enable Dulicate Item Name Cleanup (enabledulicateitemnamecleanup) | This setting takes duplicate item names with separate internal IDs and adds a prefix of ‘INACTIVE-‘ to the item name that has not been updated in over 10 days. This process occurs during the archiving process. Rule is set to ‘FALSE’ by default. | |

| Enable Trinium TMS API (enabletriniumtmsapi) | Enable the Trinium TMS Invoice and Billing API setting. When enabled, this setting can suppress a trinium invoice or bill through API. Rule is set to ‘FALSE’ by default. | |

| Assign One-Order Super Batch Tote to a Cluster Pick (assign1ordersbtoacluster) | By default, a (unique) single line multi-quantity order will be assigned as a tote in a super batch task. This setting overrides the default assignment and places the order in a cluster task. Rule is set to ‘FALSE’ by default. | |

| Viewport Scaling Factor (viewportscalingfactor) | Set a fixed custom viewport for all terminals. Scaling is normally set accordingly by mobile device. Ex setting: 1.15 = +15% scaling from default device resolution | |

| RocketShipIt API Key (rocketshipitapikey) | UseRocketShipIt API key as the default for ShipHawk WMS shipping. This setting will override the default key for your ShipHawk account. | |

| Enable Wave Batch Optimiztion (enablewavebatchoptimiztion) | Enable this setting to combine all wave batches into a single wave that is not limited by a batch threshold. Rule is set to ‘FALSE’ by default. | |

| Set Pick Standards (pickstandards) | Set custom pick standards for your containers, bins, items, and units. Rule is empty by default, enter JSON string: { “seconds_per_container”: 5.0, “seconds_per_bin”: 30.0, “seconds_per_item”: 15.0 “seconds_per_unit”: 2.0 } | |

| Enable LOV Table for Putaway Rules (enablelovtableforputawayrules) | When enabled, this setting uses LOV tables to represent putaway rules. This means putaway rules are defined in this table. Rule is set to ‘FALSE’ by default. | |

| Enable LOV Table for Allocation Rules (enablelovtableforallocationrules) | When enabled, this setting uses LOV tables to represent allocation rules. This means allocation rules are defined in this table. Rule is set to ‘FALSE’ by default. | |

| Enable Strong Password Enforcement (enablestrongpasswordenforcement) | This setting requires users to have a password with at least 8 characters, one upper case letter, one number, and one special character. Rule is set to ‘FALSE’ by default. | |

| Minimum Password Length (must be at least 6) (minimumpasswordlength) | This setting requires users to have a minimum password length. A minimum of ‘6’ characters will be required by default. | |

| Minimum Password Elements (minimumpasswordelements) | This setting requires a minimum number of password elements derived from: upper, lower, number and special characters. Rule is set to ‘3’ by default. | |

| Maximum Percent Bin Cube Utilization (maximumpercentbincubeutilization) | This setting setts the default rate at which a bin cube is used. Rule is set to ‘100’ percent by default. | |

| Use Default BOL Commity, NMFC, Class Settings (usedefaultbolnmfc) | This setting will use BOL Commodity, NMFC, and Class settings instead of item-based settings. Rule is set to ‘FALSE’ by default. | |

| Suggested Putaway Display Limit on Carts (suggestedputawaydisplaylimitoncarts) | This setting sets an item count limit that stops suggesting putaway bins for cart-based receipts when the limit is reached. This setting only applies to cart-based putaway to provide the operator insight on where the cart will travel. Rule is set to ‘35’ by default. This means a list of 35 items on a cart will all have suggested bins computed on the page. | |

| Enable Operator-Directed Pick Sequence (enableoperatordirectedpicksequence) | This rule enables an operator-directed picking sequence for order picks. When enabled, a list of picks is presented to the operator, allowing them to select the next pick they want to perform from any remaining pick in the list. This setting is useful when the travel sequence is not the best pallet building sequence based on item weight and cube. Rule is set to ‘FALSE’ by default. | |

| Enable ShpHawk API (enableshiphawkap) | Use ShipHawk API key as the default for ShipHawk WMS shipping. This will override RocketShipIt as the shipping service. Rule is set to ‘FALSE’ by default. | |

| ShipHawk API Key (shiphawkapikey) | Use this field to enter your ShipHawk API key. Default key is ‘482226fba594ebccb227733221edcd47’ | |

| Integrated Pick/Pack Process (pickandpack) | Update this setting to enable integrated picking and packing that allows for JSON as an option. | |

|

|

||

| Alloc Group Roots for Forward, B/S and Reserve (allocationgrouprootids) | This setting is used for replenishment of outbound groups. This rule sets allocation group root IDs to forward, backstock, and reserve groups. Root IDs are used to asses inventory levels in each outbound group. Inventory is replenished from backstock or reserve to forward. Rule is empty by default, enter JSON string: { “forward”: “FORWARD”, “backstock”: “BACKSTOCK”, “reserve”: “RESERVE”, “minimumqty”: 30, “urgentqty”: 10 } | |

| Auto-Release and Print (enableautoreleaseandprint) | This setting enables auto-release and auto-print. Note: This setting will only work if the auto-releasing and printing logic has been defined for your account. Rule is set to ‘FALSE’ by default. | |

| Display Unshipped (Quantity) on Admin Page (displayunshipped) | This setting can be used to disable or enable the auto-releasing and printing logic that has been defined for an account. Rule is set to ‘FALSE’ by default. | |

| Enable Count Plan by Item (enablecountplanbyitem) | This setting allows operators to list and use Items/SKUs in the bin count plan table instead of Bin IDs. This means counting happens by item rather than bin. Note: If enabled, an item id element must exist in the bin count plan table. (See rule below) Rule is set to ‘TRUE’ by default. | |

| Alter Table bincountplan Add Column plan_item_id | Add item id to bin count plan table. This setting is needed for the ‘Enable Count Plan by Item’ rule to work. | |

| Alter Table customer Add Column cust_label_print Alter Table customer Add Column cust_confirm_as_packed | Add new customer table elements that identify when to create SSC18 labels (Pack or Ship), and when to confirm shipments into NetSuite (Packed or Shipped). Rule is set to ‘Shipped’ by default. | |

| Enable Perfect Match Allocation (enableperfectmatchallocation) | This setting will allocate perfect match quantities to needed quantities of inventory, regardless of the outbound group sequence the inventory is located in. Rule is set to ‘TRUE’ by default. | |

| Alter Table archivesalesorder Add Column so_addr3 Alter Table address Add Column addr_addr3 | Add Address Line 3 to salesorder and address tables. NetSuite has an optional Address Line 3 that can be enabled in the Address Form if needed for longer addresses. | |

| Enable SLSQ Wave Picking (enableslsqwavepicking) | Single Line Single Quantity (SLSQ) orders are defined in Super Batch batches by default. This setting will isolate SLSQ ordrs from Super Batch batches and create a Single Wave batch pick. A set of labels for this pick will be printed at wave release. Rule is set to ‘FALSE’ by default. | |

| Disable Putaway Dropdown List (disableputawaydropdownlist) | This setting disables the standard putaway dropdown list. If your ShipHawk WMS setup requires operators to scan Container or Item IDs for putaway, then this rule should be set to ‘TRUE’ so the dropdown can be disabled for performance. Rule is set to ‘FALSE’ by default. | |

| Enable SPS V2 (enablespsv2) | Enable version 2.0 of the SPS Retail Label and Pack List Subsystem. This API supports the creation of Pack Lists and SSCC18 Labels that are customer/retailer specific. Version 2.0 is a JSON/REST-based API. Rule is set to ‘FALSE’ by default. | |

| Enable HAZMAT Listing on BOL (enablehazmatlistingonbol) | This setting lists hazmat data on the VICS BOL in the ‘Carrier Informaiton’ section. When hazmat data is listed, handling units and package data are suprressed. Commodity description on BOL will contain: UN ID, Proper Shipping Name, Hazmat Class, Packaging Class. Rule is set to ‘FALSE’ by default. | |

| Enable Font Awesome Fonts (enablefontawesomefonts) | This setting will enable font awesome fonts on the ShipHawk WMS website. See:https://fontawesome.com Rule is set to ‘FALSE’ by default. | |

| Font Awesome Icon Color (fontawesomeiconcolor) | Use this rule to change the default ShipHawk WMS logo colors using font awesome colors. Rule is set to ‘#295177’ by default, which is the default ShipHawk WMS logo color. | |

| Enable Blind Physical Count (enableblindphysicalcount) | This setting will make physical counts blind, which means the expected quantities for items in the bin will not be displayed. Rule is set to ‘FALSE’ by default. | |

| Suppress Container Merge Alert (supprersscontainerrmergealert) | This setting will disable the container merge alert, which informs operators of containers in inbound groups that will be automatically merged. Rule is set to ‘FALSE’ by default. | |

| Enable Crossdock Demand (enablecrossdockdemand) | Add a crossdock demand table for API crossdock demand. This table will display open order demand from the ERP system. Rule is set to ‘FALSE’ by default. | |

| Alter Table salesorder, archivesalesorder salesorderdetail, archivesalesoderdetail Add Column so_header_attributes | Add header and detail attributes to salesorder and salesorderdettail tables that can store a JSON object defined in the API. A user would want to enable this rule if they have defined custom elements. | |

| API Authentication Token (x-token) | If an external API is used, this rule sets the custom API token for authentification. Rule is set to ‘ShipHawk WMS’ by default. | |

| Filter Item Inventory by Division (filteriteminventorybydivision) | Use this setting to enable a filtered view of your inventory by assigned division. Rule is set to ‘FALSE’ by default. | |

| Alter Table item Add Column item_division | Add item division, which will be used as a filter on the search/update page. This filter process is enabled by ‘Filter Item Inventory by Division’ Rule. | |

| Bypass Kit Pricing Breakdown (bypasskitpricingbreakdown) | This setting will bypass the breakdown pricing of a kit to its individual components. This will result in each component being set to the entire kit price. A user would want to enable this rule if they have the kit and its price listed on packing documents. Rule is set to ‘FALSE’ by default. | |

| Enable Dynamic Bill or Materials (BOM) (enabledynamicbom) | Enables the use of a dynamic BOM for assembling and disassembling. Dynamic BOMs are operator defined lists of Inventory Items needed to create another item Rule is set to ‘FALSE’ by default. | |

| API Directory Path (apidirectorypath) | This rule establishes the directory path for API File processing. Path is ‘C:/Program Files/ShipHawk WMS/prod/files/’ by default. | |

| Alter Table podetail Add Column po_detail_attributes, po_confirm_date | Add detail attributes to purchase order (PO) detail tables. Add purchase order element to record confirm date of the PO. | |

| Alter Table binlocation Add column bin_cube_remain, bin_compute_cube_remain | Add columns bin cube remain and bin compute cube remain to support cube-cased putaway. | |

| Shipping Labels per Pallet (shippinglabelsperpallet) | Use this rule to set the number of shipping labels to be generated per pallet for LTL shipments. This rule only applies when pallet building is used for an order, otherwise a single label per container shipped will be printed. Rule is set to print ‘2’ labels per pallet. | |

| Alter Table podetail Add Column po_confirm_date | Add po confirm date element to purchase order detail table to record the confirmation date of the purchase order. | |

| API Controls, by Host, Location, division, API (apicontAPI Controls, by Host, Location) | This setting can define API controls by host, location, division, and API using JSON. Rule is empty by default, enter JSON string: { “API”: { “loc”: { “div”: { “940”: true, “943”: true, “944”: true, “945”: true, “947”: true, } } } } | |

| Enable Print Sequence Optimization enableprintsequenceoptimization) | This setting will change the default printing order and print based on the travel paths of the picks being released instead. Rule is set to ‘FALSE’ by default. | |

| Do Not Confirm Receipt in Realtime (donotconfirmreceiptinrealtime) | Use this rule to disable realtime receipt confirmation. A user would want to enable this rule if they request receipt confirmation through the Administration page instead. Scheduled receipt confirm processes can also be used for ‘Purchase Orders Received Complete’. Rule is set to ‘FALSE’ by default. | |

| Do Not Confirm Shipment in Realtime (donotconfirmshipmentinrealtime) | Use this rule to disable realtime shipment confirmation when processing a shipment. A user would want to enable this rule if their shipping process is performed by container, and a time delay must be used so that the operator can ship all containers in the shipment before it is confirmed to the ERP. Rule is set to ‘FALSE’ by default. | |

| Require Pick Complete Before Packing Can Begin (requirepickcompletebeforepacking) | This setting will prohibit packing if an order is not picked 100% complete or resolved. Rule is set to ‘FALSE’ by default. | |

| Enable FEDEX One Rate Pricing (enablefedexoneratepricing) | This setting will enable FedEx One Rate service pricing. Rule is set to ‘FALSE’ by default. | |

| Enable Capture of Daily Effective Rate (enablecaptureofdailyeffectiverate) | This setting will capture the non-negotiated rate for a UPS shipment in addition to the negotiated rate. When enabled, the rate will take more time to execute. Rule is set to ‘FALSE’ by default. | |

| Enable One World Rules (enableoneworldrules) | Use this setting to enable one-world logic in API transactions. This logic includes subsidiaries. Rule is set to ‘FALSE’ by default. | |

| Suppress Using Container ID (suppressusingcontainerid) | This setting will prevent the use of Container IDs during receiving and moves. Only enable this option if the ‘Auto-Create Container ID Data Receiving’ and ‘Auto-Create Container ID Move’ rules are also enabled. Rule is set to ‘FALSE’ by default. | |

| Validate Receiving Cart ID (validatereceivingcartid) | When enabled, this rule will only validate Receipt Card IDs that are scanned at receiving. This differs from the default, where any Cart ID type is be scanned at receiving. Rule is set to ‘FALSE’ by default. | |

| Suppress BOL (suppressbol) | This setting will prevent BOLs from being printed for any shipment. It will also disable the creation of BOLs under the Administration page. Rule is set to ‘FALSE’ by default. | |

| Print Ship Labels At Packing (printlabelsatpacking) | This setting determines whether labels are printed at packing. This is the same logic applied to the ‘Print Ship Labels at Receiving’ rule. Rule is empty by default, enter JSON string: { “print_label_default”: “NO”, “print_label_default_qty”: 1 } | |

| Suppress Confirming Adjustments to ERP (suppressconfirmingadjustmentstoerp) | This rule will prevent confirmation of inventory adjustments to the ERP system through API. This rule is intended to be used during the full physical cycle counting process so individual adjustments are not posted while counts are reconciled. The updated inventory balance will post to the ERP system once, rather than post numerous individual adjustments. Rule is set to ‘FALSE’ by default. | |

| Bypass Pick Profile Page (bypasspickprofilepage) | When enabled, the Pick Profile page in ShipHawk WMS is bypassed. Rule is set to ‘FALSE’ by default. | |

| Enable Order Line Edting (enableorderlineediting) | This setting allows editing of order line quantities from the Administration Details page. From this page, an operator can set an order line value to ‘0’, or reduce the quantity to any value less than the ordered amount. Rule is set to ‘FALSE’ by default. | |

| Do Not Allocate Days After Ship Date (donotallocatedaysaftershipdate) | This setting prevents orders from being allocated based on if their ship date is > than a certain number of days after the current date. | |

| Freight Quote API (freightquoteapi) | This setting directs orders to freight quote APIs- either PLAN (for Shipments) or BUILD (for Orders). Enter your Freight Quote API as a string using this rule. | |

| Print Case Labels At Receiving | This setting determines whether Case Labels are printed at receiving. Rule is empty by default, enter JSON string: { “print_label_default”: “NO”, “print_label_default_qty”: 1 “print_label_printer”: “0” } | |

| Enable Ship Label Logo (enableshiplabellogo) | Use this setting to add a custom logo to print on the ship label. When enabled, this rule will print the logo on the label if a URL exists in salesorder.so_rep_id. Rule is set to ‘FALSE’ by default. | |

| Default Ship Label Logo (defaultshiplabellogo) | Use this field to enter a default URL for every order if a specific URL is not defined for the order. | |

| Enable Direct Multi Tracking Entry (enabledirectmultitrackingentry) | If tracking number capture is active, this setting will bypass the Receiving Tracking page and direct the operator to a multi-tracking capture form as the only option for entry. Rule is set to ‘FALSE’ by default. | |

| Enable Shipping Account Override by Shipping Service (enableaccountoverridebyservice) | Use this rule to override any default carrier settings in favor of RocketShipIt settings. Rule is set to ‘FALSE’ by default. | |

| Enable Pick List Archiving (enablepicklistarchiving) | If enabled, this setting will create PDF documents of pick lists instead of printing them. This is done so the PDF can be printed offline in case the system is not operating. Rule is set to ‘FALSE’ by default. | |

| Create Table binadjustment | This rule will create a new Bin Adjustment table that captures inventory adjustment requests at the bin level that are sent by the ERP system. | |

| Enable Alert Page (enablealertpage) | This setting will enable the generic Alert page. Rule is set to ‘TRUE’ by default. | |

| Enable Batch Shipping (enablebatchshipping) | This setting will ship every order in a batch at once when task type is ‘Batch’ or ‘Super Batch’. When this rule is triggered, the weight and dimensions of the orders are captured at packing. Rule is set to ‘TRUE’ by default. | |

| Integrated Packing/Shipping Process (packandship) | This setting will enable the integrated packing and shipping process. Rule is set to ‘FALSE’ by default. | |

| Integrated Pick/Pack Process (pickandpack) | This setting will enable the integrated picking and packing process. Rule is set to ‘FALSE’ by default. | |

| Enable Auto Pack Remaining to Current Container (enableautopackremaining) | This setting will auto-pack the remainder of a container when a user manually clicks the ‘Auto Pack Remaining’ button. Rule is set to ‘TRUE’ by default. | |

| Enable Consolidated Instructions During Pick/Pack (enableconsolidatedinstructions) | This setting will display consolidated instructions to the operator during the picking and packing process. Rule is set to ‘FALSE’ by default. | |

| Enable Code Date Entry (enablecodedateentry) | This rule allows for the entry of a code date (or lot expiration date) based on the lot code entered. Rule is set to ‘FALSE’ by default. | |

| Cycle Count Window (cyclecountwindow) | Use this rule to set the period that a bin is considered counted before directed counting will be reconsidered. Rule is set to ‘60’ day count cycle by default. | |

| Enable Ascending Order Putaway Sequence (enableascendingorderputawayseq) | When enabled, empty bins are arranged in ascending order for putaway. Ascending order means bins are arranged from smallest to largest and putaway in that order. Rule is set to ‘FALSE’ by default. | |

| Skip Pack Directive (skippackdirective) | This rule skips Pack Directive Verification. Pack Directive Verification directs users to travel to a pack station. Rule is set to ‘FALSE’ by default. | |

| Check Item Dimensions At Receiving (checkItemDimensionsAtReceiving) | This setting triggers a message that informs the operator they must capture weights and dimensions and enter them into NetSuite for an item during the receiving process. The message is triggered when any item has a LxWxH or weight of ‘0’ during receiving. Rule is set to ‘FALSE’ by default. | |

| Enable UPS Mail Innovations (MI) Manifest (enableupsmi) | Use this setting to add a UPS Mail Innovations End of Day Manifest. Rule is set to ‘FALSE’ by default. | |

| Always Ship Using Less Options (alwaysshipusinglessoptions) | This setting will always use the Less Options page if feasible, regardless of terms. Rule is set to ‘FALSE’ by default. | |

| Shipping Rates (shippingrates) | This rule will load a table of shipping rates for simple manifesting calculations that is not already provided by the carrier. Rule is empty by default, enter the JSON string: { “M4”: { “1”: 2.56, “2”: 2.56 “3”: 2.56, “4”: 2.56 “5”: 2.56, “6”: 2.56 “7”: 2.56, “8”: 2.56 “9”: 2.56, “10”: 2.56 “11”: 2.56, “12”: 2.56 “13”: 2.56, “14”: 2.56 “15”: 2.56, “16”: 2.56 } } | |

| Alter Table itemalias Add Column ia_date_last_updated date | Add item alias last updated date column to Item Alias table to track when an item alias has last been updated. | |

| Enable NII (Non-Inventory Item) Allocation (enableiiallocation) | Allow non-inventory items to be allocated to assigned pick locations. Rule is set to ‘FALSE’ by default. | |

| Enable Manual Freight Charge Entry (enablemanualfreightchargenetry) | Allow manual entry of freight charges on Ship Order page. This will replace the Shipment Authorization Number on that same page. Rule is set to ‘FALSE’ by default. | |

| Pack Edit Do Not Create SSCC18 (packeditdonotcreatesscc18) | By default, when a new Container ID is entered, it is set as the alias ID for the container and a SSCC18 is generated as the actual ID for the new container. This rule stops the creation of an SSCC18 ID for new containers created in Pack Edit. Rule is set to ‘FALSE’ by default. | |

| Schedule Orders Strictly By Priority (scheduleordersstrictlybypriority) | This setting schedules the next order to pick based off priority only, instead of assigning orders based off ship date first, then priority. Rule is set to ‘TRUE’ by default. | |

| Print Copies of Commercial Invoice (commercialinvoicecopies) | Set the default number of copies printed for commercial invoices. Rule is set to print ‘1’ commercial invoice copy by default. | |

| Enable Shipment Consolidation (enableshipmentconsolidation) | This setting lets users consolidate orders for shipment. When enabled, orders will be consolidated under the following circumstances: - Orders that share the same sales order consolidation number will be shipped together - Container IDs from two different orders scanned to the same Pallet Note: You must ensure the API does not automatically set sales order consolidation numbers, or multiple orders could be shipped together unknowingly. Rule is set to ‘FALSE’ by default. | |

| Return Service Codes for Carriers (returnservicecode) | This rule will automatically assign a carrier return service code to a return service label when a label for return is requested. Return service codes define the service being used to ship the return. By default, the forwarding label service code is used as the return service code. This rule will override the default and use the carrier’s return service code instead. This rule is applicable to UPS and FEDEX service codes only. Rule is empty by default, enter the json string: { “UPS”: “03”, “FEDEX”: “FEDEX_GROUND” } | |

| Manual Weight Required for Containers (manualweightrequiredforcontainers) | This rule will auto-set weights for containers with the same alias ID that are split using the ‘Edit Containers’ page. When set to ‘FALSE’, this rule allows split containers to be auto set with the same weight. When set to ‘TRUE’, every container weight must be captured and inputted manually. | |

| Enable Unlimited Item Alias (enableunlimiteditemalias) | This setting provides access to a secondary Item Alias table. This Item Alias table stores unlimited item aliases, defined alias types, and customer specific aliases. Rule is set to ‘FALSE’ by default. | |

| Threshold Maximum Quantity for Batch/Super Batch Batch/Wave Units (pickbatchmaximumunits) | This rule sets the maximum units that can be placed in a single batch. Rule is set to ‘10000’ units by default. | |

| ConnectShip API Active (connectshipapiactive) | This rule connects to the UPS ConnectShip system through API. You can use UPS ConnectShip as your organizations shipping & rating service by activating the ConnectShip API. Rule is set to ‘FALSE’ by default. | |

| Print an SSCC18 id at packing for shipping containers | When enabled, this rule will create SSCC18 labels at Packing. By default, SSCC18 labels are generated at Shipping. Rule is set to ‘FALSE’ by default. | |

| Confirm Receipt Using Transfer (confirmreceiptusingtransfer) | This rule enables the use of an Inventory Transfer to post purchase order receipts. Inventory Transfers are used in this instance to facilitate entry of landed costs, or receive all items on ‘Hold’. Note: The ‘From’ location internal ID must be set for this setting to work. | |

| Print Unit Labels At Receiving (printlabelsatreceiving) | Use this rule to control whether Unit Labels are printed at receiving, and if so, set the number of copies to be printed. Rule is empty by default, enter the json string: { “print_label_default”: “YES”, “print_label_default_qty”: 0 } | |

| Auto create Container ID at Receiving (autocreatecontaineridatreceiving) | This setting will auto-generate Container IDs during receiving. This rule should be used in conjunction with the ‘Print Unit Labels At Receiving’ rule. Rule is set to ‘FALSE’ by default. | |

| Create Item Labels for Return Authorization (createreturnlabelsforrra) | This setting creates item labels for Return Authorizations. Note: The Label ID of the Return Item Label must be set for this setting to work. Rule is set to ‘FALSE’ by default. | |

| Enable Capture Photo at Receipt (enablecapturephotoatrerceipt) | This setting gives users the option to capture a photo at receipt from the Receive Item Quantity page. Rule is set to ‘FALSE’ by default. | |

| Enable allocation to assigned bin (enableassignedpickbin) | This setting allows users to set fixed bin allocation options for their inventory. If no inventory exists, then regular allocation will take over. Rule is set to ‘FALSE’ by default. | |

| Alter Table salesorderdetail, archivesalesorderdetail Add Column so_assigned_bin_id | Add table elements to support the ‘Enable allocation to assigned bin’ rule. | |

| Always Confirm ASN to ERP (alwaysconfirmasntoerp) | This setting will trigger an update to the SPS or ASN record in NetSuite when the ASN is confirmed. Rule is set to ‘FALSE’ by default. | |

| Maximum Numeric Quantity Allowed (maximumnumericquantityallowed) | Use this rule to define a maximum quantity that can be entered for moves, putaway, picks, and adjustments. Setting this value to ‘0’ means an unlimited quantity can be entered. Any negative value entered will be multiplies by ‘-1’ so it is converted to a positive value. Rule is set to ‘10000’ units by default. | |

| Auto Create Lot Expiration Date + Months (autocreatelotexpdatemonths) | Use this rule to define how lot expiration dates are determined. If the value is not empty, this rule will take the current date and add the value (in months) as the lot expiration date. Ex: If today’s date is February 1, and the value is set to 2, the lot expiration date is set to April 1. | |

| Default Receiving Status (defaultreceivingstatus) | Set the default status setting during receiving. By default, the status is set to ‘GOOD’. Enter a different status here to change the default receiving status. Rule is set to ‘GOOD’ by default. | |

| Enable Passport API (enablepassport) | Use this setting to enable Passport Shipping for international shipping via API. Rule is set to ‘FALSE’ by default. | |

| Enable Global-E API (enableglobale) | Use this setting to enable Global-E Shipping for international shipping via API. Rule is set to ‘FALSE’ by default. | |

| Enable Returnly API (enablereturnly) | Use this setting to enable Returnly as a return service via API. Rule is set to ‘FALSE’ by default. | |

| Alter Table item Add Column item_prop_65 | Add column to represent California Prop 65 requirements as an item attribute. | |

| Enable Cube Based Putaway (enablecubebasedputaway) | This setting will enable cube-based putaway logic for bins in outbound groups. Rule is set to ‘FALSE’ by default. | |

| Enable Putaway To Assigned Bin (enableputawaytoassignedbin) | This rule will enable putaway logic to set an item’s assigned bin as it’s preferred bin during putaway. Rule is set to ‘FALSE’ by default. | |

| Alter Table item Add Column item_assigned_bin_id Alter Table item Add Index itemAssignedBin | Add table elements to support ‘Enable Putaway To Assigned Bin’ rule. Add column and index to store an item’s assigned bin. | |

| Alter Table rule Add Column rule_empty_not_allowed | Add column to rule table that limits empty bins during putaway process. | |

| API URL for ShipHawk WMS | Define the default URL to use for APIs with ShipHawk WMS. (apiurl) | Default URL is ‘www.suitewm.com/swmAPI.php’ | ||

| Enable Freighquote API (enablefreightquote) | Use this setting to enable Freightquote via API. Rule is set to ‘FALSE’ by default. | |

| Inactive APIs (inactiveapis) | Use this setting to inactive specific APIs. If the API ID is listed under this setting, then the associated API will not be executed. | |

| Prohibit Reuseable Totes (prohibitreusabletotes) | Use this rule to prohibit the use of reusable totes. This setting works by prohibiting non- reusable container IDs from being re-scanned during picking. Rule is set to ‘FALSE’ by default. | |

| Enable RocketShipIt V2 (enablerocketshipitv2) | If you choose to use RocketShipIt shipping services with your instance of ShipHawk WMS, this rule will enable the usage of the cloud-based RocketShipIt API Version 2. Rule is set to ‘FALSE’ by default. | |

| Alter Table podetail Add Column po_inco_terms | Add column to purchase order detail table that decides how the receipt is confirmed to the ERP system. The options for confirming a receipt are: Perform standard item receipt process (if terms are empty) Perform inventory transfer from “intransit” to “PO Location” (If terms are FOB Factory) Note: The ‘Confirm Receipt Using Transfer’ rule must be enabled to perform an inventory transfer. | |

| Suppress Receiving Memo (suppressreceivingmemo) | This setting will disable the receiving memo option during returns processing. Rule is set to ‘FALSE’ by default. | |

| Auto create Container ID at Move (autocreatecontaineridatmove) | When enabled, this setting will auto-generate Container IDs during moves. This rule should be used in conjunction with the ‘Print Unit Labels At Receiving’ rule. Rule is set to ‘TRUE’ by default. | |

| Capture Tracking at Receipt (capturetrackingatreceipt) | When enabled, this rule will trigger the capture of a BOL or Tracking number for reference during the receiving process. Rule is set to ‘FALSE’ by default. | |

| Skip Item Verification at Picking (skipitemverificationatpicking) | This rule will skip the item verification at picking process. When this rule is DISABLED, operators will be required to scan or verify an item being picked before the item’s quantity is displayed Rule is set to ‘FALSE’ by default. | |

| Skip Container Type Capture at Packing (skipcontainertypecaptureatpacking) | This rule will skip the container type capture at packing process. When this rule is DISABLED, this process verifies the container type from the ‘Pack Container’ page. Rule is set to ‘FALSE’ by default. | |

| Skip Pack Complete Alert (skippackcompletealert) | This rule will skip the pack complete alert. When this rule is DISABLED, the operator is alerted when the packing process is finished. Rule is set to ‘FALSE’ by default. | |

| Enable Zone Order Picking (enablezoneorderpicking) | This setting enables zone picking, which limits picking activities to bins in this zone. Pick and pass picking between zone is supported with this option. Rule is set to ‘FALSE’ by default. | |

| Days After Shipment to Archive Data (daysaftershipmentdata) | Use this rule to set the number of days after a shipment is scheduled to archive the shipment data in ShipHawk WMS. Rule is set to ‘90’ days by default. | |

| Reciept of Multi-Item Container Allowed (receiptofmultiitemcontaine) | This setting allows the operator to receive a receipt when performing multi-item container packing. Rule is set to ‘FALSE’ by default. | |

| Bill Duties and Taxes to Separate Account (billdutiesseperately) | This setting allows users to bill the duties of a shipment separately from the overall cost to ship. Rule is empty by default, enter the JSON string: { “account”: “7YU8UY”, “postal_code”: “Y65RTA” “country_code”: “CA” } | |

| Create an SSCC19 id for shipping containers (packcreatesscc18id) | When enabled, this rule will auto-generate SSCC18 IDs that will be assigned to containers during packing. Rule is set to ‘FALSE’ by default. | |

| Maximum Cluster Created in a Single Wave (maximumclustertasks) | Use this rule to set the maximum cluster tasks can be created for a single wave pick. Cluster tasks assign one order to be packed per tote/container. Rule is set to ‘10000’ tasks by default. | |

| Maximum Batches Created in a Single Wave (maximumbatchtasks) | Use this rule to set the maximum batch tasks can be created for a single wave pick. Batch tasks assign multiple orders with the same characteristics to be picked in bulk. Rule is set to ‘10000’ tasks by default. | |

| Maximum Super Batches Created in a Single Wave (maximumsuperbatchtasks) | Use this rule to set the maximum super batch tasks can be created for a single wave pick. Super batch tasks assign the operator to pick one batch per tote/container. Rule is set to ‘10000’ tasks by default. | |

| Prompt Operator for Count Attribute (promptoperatorforcountattribute) | When enabled, this setting will prompt the operator to enter the number of attributes in a count. | |

| Capture Container Type at Shipping (capturecontainertypeatship) | This rule will capture the container type during the shipping process. Rule is set to ‘FALSE’ by default. | |

| Count (Manual) Verify Item Only (countverifyitemonly) | This setting will allow the operator to perform a manual count where only the item is verified. Items are not directed to a bin after the count is performed. Rule is set to ‘FALSE’ by default. | |

| Priority pack destination suffix (prioritypackdestinationsuffix) | Use this field to enter the suffix of the pack line is used for priority packing. Rule is set to ‘.P’ by default. | |

| Pre-Assigned Container IDs Defined During Picking (pickpreassignedcontainers) | This setting will automatically pre-assign containers to be used during the picking process. Rule is set to ‘FALSE’ by default. | |

| Enable Pack Add (enablepackadd) | Use this rule to add additional items to current container during packing. Rule is set to ‘FALSE’ by default. | |

| Capture Container Type at Pack (Add Only) (capturecontainertypeatpack) | This rule will capture the container type during Pack Add. This rule is used when the ‘Enable Pack Add’ rule is also enabled. Rule is set to ‘FALSE’ by default. | |

| Enable Electronic Commercial Invoice (enablecommercialinvoice) | This setting will allow you to generate and submit commercial invoices (used for shipping) electronically. Rule is set to ‘FALSE’ by default. | |

| Enable Paper Pick Operations (enablepaperpickoperations) | Enable this setting if you want to run your picking operation in ShipHawk WMS using a paper-driven process, rather than a barcode-scanning process. Rule is set to ‘FALSE’ by default. | |

| Always Ship Using More Options (alwaysshipusingmoreoptions) | This setting will enable the ‘More Options’ button on the ‘Ship Container’ page in ShipHawk WMS. This page allows operators to change the address, carrier, service and more before shipping. Rule is set to ‘FALSE’ by default. | |

| Only Ship Single Containers (onlyshipusingsinglecontainers) | This rule will only allow you to ship containers one-by-one. Rule is set to ‘FALSE’ by default. | |

| ShipHawk WMS Version 1 is Active | Use this setting to activate Version 1 (V1) of ShipHawk WMS. (version1isactive) | Rule is set to ‘FALSE’ by default. | ||

| Enable Accept All Cycle Counts (enableacceptallcyclecounts) | This setting will accept all counts after they have been executed, regardless of exceptions. Rule is set to ‘FALSE’ by default. | |

| Enable Local Scale Driver (enablelocalscaledriver) | Enable this rule to allow your local scale to connect and print using ShipHawk WMS. Rule is set to ‘FALSE’ by default. | |

| Pack Verify Prohibited Task Types (packverifyprohibitedtasktypes) | Enter any prohibited task type as a string in this field. This rule will ensure prohibited task types listed must be verified before packing. Rule is set to ‘FALSE’ by default. | |

| Pack With Order as Alias Container ID (packwithaliascontainerid) | This setting will pack orders using the alias container ID, instead of the original container id (SSCC18 ID). Rule is set to ‘FALSE’ by default. | |

| Receipt Documents Managed by Location (receiptdocumentsmanagedbylocation) | This setting will organize all the documents generated at receiving by Location. Rule is set to ‘FALSE’ by default. | |

| Default Cycle Count Plan Parameters (defaultcyclecountplanparameters) | This setting sets the default parameters for cycle counts, including the cycle count period. The rule is stored as a JSON string, and the values represent the number of days it takes items in each group to be placed on a count list. To enable, enter the JSON string: { “A”:33, “B”:20 “C”:12 } | |

| Enable Wave Picking (enablewavepicking) | This setting allows operators to perform wave picking. Wave picking is when when all items are picked for an entire wave and placed in a container, unsorted. Rule is set to ‘FALSE’ by default. | |

| FedEx SmartPost Hub ID (fedexsmartposthubid) | This field stores your FedEx SmartPost Hub ID. This is required to use FedEx SmartPost as a shipping option. Enter your Hub ID as a string in this field if you are using FedEx SmartPost. Rule is set to ‘FALSE’ by default. | |

| Ship Confirm: Do Not Alter ERP Line Items (donotaltererplineitems) | When enabled, this setting will withhold altering order line items when the Ship Confirm status is send to your ERP system. Rule is set to ‘FALSE’ by default. | |

| Enable EasyPost Rate Shopping (enableeasypostrateshopping) | This rule will enable EasyPost in your ShipHawk WMS account. EasyPost allows you to rate shop, create labels, and manifest international shipments. Rule is set to ‘FALSE’ by default. | |

| Decimal Inventory Management Settings (decimalinventorymanagement) | This setting sets the standard format for decimals when used for inventory data. Rule is empty by default, enter JSON string: { “active”: false, “step”: 0, “format”: “#” } | |

| Enable Order Type For Pack Rule (enableordertypeforpackrule) | This setting enables the ‘Order Type’ field when packing an order. Rule is set to ‘FALSE’ by default. | |

| Do Not Set ERP Ship Cost (donotseterpshipcost) | This setting prevents the ship cost, which is generated in ShipHawk WMS, from being posted to the ERP system. Rule is set to ‘FALSE’ by default. | |

| Confirm Receipt to PO Locaation (confirmreceipttopolocation) | This setting is used to manage consignment inventory. Receipt is confirmed to the PO Location in the ERP system. Rule is set to ‘FALSE’ by default. | |

| Use Standard ASN Object (usestandardasnobject) | This rule ensures standard ASN tables are being used in your instance of ShipHawk WMS. Rule is set to ‘FALSE’ by default. | |

| SSCC18 GS1 (sscc18gs1) | You can enter a standard GS1 segment to use for your SSCC18 labels in this field. GS1 segment is ‘8889120’ by default. | |

| Enable Container Pick Operations (enablecontainerpickoperations) | This setting enables specific container/lot pick operations. These operations are used for pallet or slot storage of inventory where auto-assignment of containers/lots is not practical. Rule is set to ‘FALSE’ by default. | |

| Enable Receiving Messages Display (enablereceivingmessagesdisplay) | This setting allows your ShipHawk WMS platform to display messages to your operator. Rule is set to ‘FALSE’ by default. | |

Examples:

| Type | LOV Description | LOV Code | LOV Attribute 1 |

|---|---|---|---|

| RULE | Verification of Items During Packing (boolean) | packverifyitems | TRUE |

| RULE | Allow Full Case Picks | pickallowfullcase | TRUE |

| RULE | Always Ship Using Less Options (boolean) | alwaysshipusinglessoptions | FALSE |

| RULE | Always Ship Using More Options (boolean) | alwaysshipusingmoreoptions | FALSE |

| RULE | API URL for ShipHawk WMS (string) | apiurl | www.suitewm.com |

| RULE | Auto create Container ID at Move (boolean) | autocreatecontaineridatmove | TRUE |

| RULE | Auto create Container ID at Receiving (boolean) | autocreatecontaineridatreceiving | FALSE |

| RULE | Auto Create Lot Exp Date Months (integer) | autocreatelotexpdatemonths | 0 |

| RULE | Bill Duties and Taxes to Separate Accoun (json) | billdutiesseparately | FALSE |

| RULE | Bypass Pick Profile Page (boolean) | bypasspickprofilepage | FALSE |

| RULE | Capture Container Type at Pack (Add Only) (boolean) | capturecontainertypeatpack | TRUE |

| RULE | Capture Container Type at Shipping | capturecontainertypeatship | FALSE |

| RULE | Capture Container Weight at Packing (boolean) | captureweightatpack | FALSE |

| RULE | Capture Tracking at Receipt (boolean) | capturetrackingatreceipt | FALSE |

| RULE | Carrier Suffix Required in NetSuite (boolean) | carriersuffixrequired | FALSE |

| RULE | Confirm Receipt To PO Location (boolean) | confirmreceipttopolocation | TRUE |

| RULE | Confirm Receipt Using Transfer (json/boolean) | confirmreceiptusingtransfer | |

| RULE | ConnectShip API Active (boolean) | connectshipapiactive | FALSE |

| RULE | Count (Manual) Verify Item Only (boolean) | countverifyitemonly | FALSE |

| RULE | Create a Return Ship Label with Shipment (boolean) | createreturnshiplabel | FALSE |

| RULE | Create an SSCC18 id for shipping containers (boolean) | packcreatesscc18 | TRUE |

| RULE | Create Item Labels for Return Authorization (boolean) | createreturnlabelsforra | FALSE |

| RULE | Cycle Count Window (integer) | cyclecountwindow | 60 |

| RULE | Days After Shipment to Archive Data | archivedays | 90 |

| RULE | Decimal Inventory Management Settings (json) | decimalinventorymanagement | {“”active””: false... |

| RULE | Default Cycle Count Plan Parameters (json) | defaultcyclecountplanparameters | {“”A””:33,”“B””:20, |

| RULE | Default Receiving Status (string) | defaultreceivingstatus | GOOD |

| RULE | Default Ship Label Logo (url) | defaultshiplabellogo | |

| RULE | Disable Putaway Dropdown List (boolean) | disableputawaydropdownlist | FALSE |

| RULE | Display Item Alias with Item Name (boolean) | displayitemalias | FALSE |

| RULE | Do Not Allocate Days After Ship Date (integer) | donotallocatedaysaftershipdate | |

| RULE | Do Not Set ERP Ship Cost (boolean) | donotseterpshipcost | FALSE |

| RULE | Enable Accept All Cycle Counts (boolean) | enableacceptallcyclecounts | FALSE |

| RULE | Enable Alert Page (boolean) | enablealertpage | TRUE |

| RULE | Enable Ascending Order Putaway Sequence (boolean) | enableascnedingputawayseq | FALSE |

| RULE | Enable Auto Pack Remaining to Current Container (boolean) | enableautopackremaining | TRUE |

| RULE | Enable Batch Shipping (boolean) | enablebatchshipping | FALSE |

| RULE | Enable Borderlinx API (boolean) | enableborderlinx | TRUE |

| RULE | Enable Capture of Daily Effective Rate (boolean) | enablecaptureofdailyeffectiverate | TRUE |

| RULE | Enable Capture Photo at Receipt (boolean) | enablecapturephotoatreceipt | FALSE |

| RULE | Enable Code Date Entry (boolean) | enablecodedateentry | FALSE |

| RULE | Enable Container Pick Operations (boolean) | enablecontainerpickoperations | FALSE |

| RULE | Enable Cube Based Putaway (boolean) | enablecubebasedputaway | FALSE |

| RULE | Enable Direct Multi Tracking Entry (boolean) | enabledirectmultitrackingentry | FALSE |

| RULE | Enable EasyPost Rate Shopping (boolean) | enableeasypostrateshopping | FALSE |

| RULE | Enable Electronic Commercial Invoice (boolean) | enablecommercialinvoice | FALSE |

| RULE | Enable Freighquote API (boolean) | enablefreightquote | FALSE |

| RULE | Enable Global-E API (boolean) | enableglobale | TRUE |

| RULE | Enable Local Scale Driver (boolean) | enableLocalScaleDriver | FALSE |

| RULE | Enable Manual Freight Charge Entry (boolean) | enablemanualfreightchargeentry | TRUE |

| RULE | Enable Order Line Edting (boolean) | enableorderlineediting | TRUE |

| RULE | Enable Order Type For Pack Rule (boolean) | enableordertypeforpackrule | FALSE |

| RULE | Enable Pack Add (boolean) | enablepackadd | FALSE |

| RULE | Enable Paper Pick Operations (boolean) | enablepaperpickoperations | FALSE |

| RULE | Enable Passport API (boolean) | enablepassport | FALSE |

| RULE | Enable Putaway Logic for Last Known Bin (boolean) | enablelastknownbin | TRUE |

| RULE | Enable Putaway To Assigned Bin (boolean) | enableputawaytoassignedbin | FALSE |

| RULE | Enable Receiving Message Display (boolean) | enablereceivingmessagedisplay | FALSE |

| RULE | Enable Returnly API (boolean) | enablereturnly | FALSE |

| RULE | Enable RocketShipIt V2 (boolean) | enablerocketshipitv2 | TRUE |

| RULE | Enable Ship Label Logo (boolean) | enableshiplabellogo | TRUE |

| RULE | Enable Shipment Consolidation (boolean) | enableshipmentconsolidation | FALSE |

| RULE | Enable Shipping Acount Override by Shipping Service (boolean) | enableaccountoverridebyservice | FALSE |

| RULE | Enable SPS V2 (boolean) | enablespsv2 | TRUE |

| RULE | Enable Unlimited Item Alias (boolean) | enableunlimiteditemalias | FALSE |

| RULE | Enable Wave Picking (boolean) | enablewavepicking | FALSE |

| RULE | Enable Zone Order Picking (boolean) | enablezoneorderpicking | FALSE |

| RULE | FedEx SmartPost Hub ID (string) | smartposthubid | 5802 |

| RULE | Final Shipping Container Used in Picking (boolean) | pickintoshipping | FALSE |

| RULE | Inactive APIs (string) | inactiveapis | |

| RULE | Integrated Packing/Shipping Process (boolean) | packandship | FALSE |

| RULE | Integrated Pick/Pack Process (boolean) | pickandpack | FALSE |

| RULE | Manual Weight Required for Containers (boolean) | manualweightrequiredforcontainers | FALSE |

| RULE | Maximum Batches Created in a Single Wave (integer) | maximumbatchtasks | 100000 |

| RULE | Maximum Cluster Created in a Single Wave (integer) | maximumclustertasks | 100000 |

| RULE | Maximum Numeric Quantity Allowed (integer) | maximumnumericquantityallowed | 10000 |

| RULE | Maximum Super Batches Created in a Single Wave (integer) | maximumsuperbatchtasks | 100000 |

| RULE | Maximum Totes in a Cluster (integer) | pickmaximumtotes | 4 |

| RULE | Maximum Totes in a Super Batch (integer) | pickmaximumsbtotes | 6 |

| RULE | Only Ship Single Containers (boolean) | onlyshipsinglecontainers | FALSE |

| RULE | Pack Edit Do Not Create SSCC18 (boolean) | packeditdonotcreatesscc18 | FALSE |

| RULE | Pack Verify Prohibited Task Types (String) | packverifyprohibitedtasktypes | NONE |

| RULE | Pack With Order as Alias Container ID (boolean) | packwithaliascontainerid | FALSE |

| RULE | Pre-Assigned Container IDs Defined During Picking (boolean) | pickpreassignedcontainers | |

| RULE | Print an SSCC18 id at packing for shipping containers (boolean) | packprintsscc18 | FALSE |

| RULE | Print Case Labels At Receiving (json/boolean) | printcaselabelsatreceiving | {“”print_label ... |

| RULE | Print Copies of Commercial Invoice (int) | commercialinvoicecopies | 1 |

| RULE | Print Ship Labels At Packing (json/boolean) | printlabelsatpacking | |

| RULE | Print Unit Labels At Receiving (json/boolean) | printlabelsatreceiving | {“”print_label ... |

| RULE | Priorty pack destination suffix (string) | priortypackdestinationsuffix | .P |

| RULE | Prompt Operator for Count Attribute (string) | capturecountattribute | |

| RULE | Receipt Documents Managed by Location (boolean) | receiptdocumentsmanagedbylocation | FALSE |

| RULE | Receipt of Multi-Item Container Allowed (boolean) | receiptmultiitemcontainer | TRUE |

| RULE | Receipt Percent Overage Allowed (20 = 20% Overage) (integer) | receiptpercentoverageallowed | 20 |

| RULE | Return Service Codes for Carriers (json/boolean) | returnservicecode | {“”UPS””: “”03””,... |

| RULE | Ship Confirm: Do Not Alter ERP Line Items (boolean) | donotaltererplineitems | FALSE |

| RULE | Skip Container Type Capture at Packing (boolean) | skipcontainertypecaptureatpacking | FALSE |

| RULE | Skip Item Verification at Picking (boolean) | skipitemverificationatpicking | FALSE |

| RULE | Skip Pack Complete Alert (boolean) | skippackcompletealert | FALSE |

| RULE | Skip Pack Directive (boolean) | skippackdirective | FALSE |

| RULE | SSCC18 GS1 (string) | sscc18gs1 | 8889120 |

| RULE | ShipHawk WMS Version 1 is Active (boolean) | version1isactive | FALSE |

| RULE | Suppress BOL (boolean) | suppressbol | FALSE |

| RULE | Suppress Confirming Adjustments to ERP (boolean) | suppressconfirmingadjustmentstoerp | FALSE |

| RULE | Suppress Receiving Memo (boolean) | suppressreceivingmemo | FALSE |

| RULE | Suppress Using Container ID (boolean) | suppressusingcontainerid | FALSE |

| RULE | Threshold Maximum Quantity for Batch/Super Batch/Wave Units (integer) | pickbatchmaximumunits | 10000 |

| RULE | Threshold Quantity for Batch/Super Batch (integer) | pickbatchthreshold | 30 |

| RULE | Use Standard ASN Object (boolean) | usestandardasnobject | TRUE |

| RULE | Verification of Items During Packing (boolean) | packverifyitems | TRUE |

JSON for Decimal Inventory Management Rule:

{

"active": true,

"step": "0.25",

"format": "#.##"

}

JSON for Print Labels at Receiving Rule:

{

"print_label_default" : "YES",

"print_label_default_qty" : 1

}

Roles¶

Usage:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 |

|---|---|---|---|---|

| ROLE | Description of the role | Specific Code that will match value in Role Table | Sorting order | ERP Internal ID for this Role |

Examples:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 |

|---|---|---|---|---|

| ROLE | Administrator | ADMINISTRATOR | 1 | 3 |

| ROLE | Manager | MANAGER | 2 | 4 |

| ROLE | Operator | OPERATOR | 3 | 5 |

The LOV Table relates to the ROLE table in ShipHawk WMS which is defined as follows:

| Role Name | Role Definition |

|---|---|

| The LOV Code being used for this role | A JSON Object which describes this role |

Examples:

| Role Name | Role Definition (see sample bject below) |

|---|---|

| ADMINISTRATOR | {“UnAuthorizedForms”: [“none”],”UnAuthorizedOptions”: [“none”]} |

Tip

It is very useful to use a JSON Editor to compose/validate this data, and then post into this table. It is intended that this data is established once at the beginning of a project sine it is rarely changed.

Below is a sample Role Definition:

{

"UnAuthorizedForms": [

"Pack",

"Count",

"Search"

],

"UnAuthorizedOptions": [

"ReviewResults",

"ResolveCounts",

"SearchforPOASN"

]

}

Note

Any option, button, or form can be de-authorized for any role.

Location¶

Usage:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 |

|---|---|---|---|

| LOCATION | Description of Physical Warehouse Location | ERP Internal ID for this Physical Location | Sorting order |

Examples:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 |

|---|---|---|---|

| LOCATION | East Coast Warehouse | 1 | 1 |

| LOCATION | West Coast Warehouse | 2 | 2 |

Note

Locations should only be defined for PHYSICAL sites, and not virtual stores for isolating inventory. The Internal IDs should relate to the “top level” physical sites defined within the ERP.

Division¶

Usage:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 | LOV Attribute 3 | LOV Attribute 4 |

|---|---|---|---|---|---|---|

| DIVISION | Description of the Division | ERP Internal ID for this Division | Sorting order | Prefix used in packlist processing | Return Address JSON | BOL Material Class |

Examples:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 | LOV Attribute 3 | LOV Attribute 4 |

|---|---|---|---|---|---|---|

| DIVISION | Retail | 2 | 1 | RT | PO Box 325, Highland MD, USA | Electronics |

| DIVISION | Wholesale | 5 | 2 | WS | PO Box 543, Highland MD, USA | Electronics |

The Return Address element is represented with a JSON object and can represent multiple return addresses for different Locations (for the Division), and different Customers (for drop shipments). Return Addresses are listed on all Pack Lists, Shipping labels, BOLs, Commercial Invoices and other logistics-related documents.

{

"returnAddress": {

"company": "SWM Inc.",

"addr1": "1234 Maple Street",

"city": "Highland",

"state": "MD",

"zip": "20777",

"countrycode": "US",

"phone": "555-111-2222",

"customssigner": "Customer Service"

},

"EAST-DC": {

"returnAddress": {

"company": "SWM Inc.",

"addr1": "7654 Pine Street",

"city": "Highland",

"state": "MD",

"zip": "20777",

"countrycode": "US",

"phone": "000-000-0000",

"customssigner": "Customer Service"

}

},

"WEST-DC": {

"returnAddress": {

"company": "SWM Inc.",

"addr1": "4321 Oak Street",

"city": "Vista",

"state": "CA",

"zip": "92081",

"countrycode": "US",

"phone": "000-000-0000",

"customssigner": "Customer Service"

}

},

"WALMART": {

"returnAddress": {

"company": "Walmart.com",

"addr1": "1901 SE 10th St",

"city": "Bentonville",

"state": "AR",

"zip": "72712",

"countrycode": "US",

"phone": "000-000-0000",

"customssigner": "Customer Service"

}

}

}

The BOL Material Class element is represented with a JSON object and represents system-wide defaults for the National Motor freight Code (NMFC), Commodity Description, and Commodity Freight Classification to be listed on the BOL for shipments under this Division unless Item-specific data is set. An example is shown below:

{

"item_nmfc": "100240",

"item_classification": "100",

"item_commodity": "METAL/IRON/GLASS"

}

Note

Division may frequently be associated with ERP’s or NetSuite’s “Class” attribute, but it need not be. Distinct Divisions should only be defined if the operations are to be maintained distinctly within the warehouse.

Classification¶

Usage:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 |

|---|---|---|---|

| CLASS | Description of the Class | ERP Internal ID for this Class | Sorting order |

Examples:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 |

|---|---|---|---|

| CLASS | EQUIPMENT | 8 | 1 |

| CLASS | APPAREL | 5 | 2 |

Ownership of Inventory¶

Usage:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 |

|---|---|---|---|---|

| OWNER | Description of Ownership for Location | ERP Internal ID for this Owner Location | Label Displayed During Receipt | Putaway Strategy Rule Set |

Examples:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 |

|---|---|---|---|---|

| OWNER | Consignment for East Warehouse | 445 | Consignment | PUT-CONSIGN-EAST |

| OWNER | Consignment for East Warehouse | 446 | Consignment | PUT-CONSIGN-WEST |

Note

This feature must be used with the rule setting “Confirm Receipt To PO Location (boolean)”. All items that are received against a matching PO Location will inherit the Putaway Strategy defined for that class of inventory ownership

Workstation¶

Usage:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 | ||

|---|---|---|---|---|---|

| WORKSTATION | Description of Workstation location and usage | Internal Code | Sorting Order | A JSON Object which describes this Workstation | ||

Examples:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 |

|---|---|---|---|---|

| WORKSTATION | Pack Station 1 | 1 | 1 | {“printer_pdf”:”2356”, “printer_raw”:”654”, “scale_id”:”433”} |

| WORKSTATION | Pack Station 2 | 2 | 2 | {“printer_pdf”:”7366”, “printer_raw”:”399”, “scale_id”:”433”} |

| WORKSTATION | Pack Station 3 | 3 | 3 | {“printer_pdf”:”3777”, “printer_raw”:”632”, “scale_id”:”367”} |

| WORKSTATION | Receving Dock 1 | 4 | 4 | {“printer_pdf”:”3232”, “printer_raw”:”777”, “scale_id”:”232”} |

| WORKSTATION | Receving Dock 2 | 5 | 5 | {“printer_pdf”:”6464”, “printer_raw”:”777”, “scale_id”:”232”} |

| WORKSTATION | Receving Dock 3 | 6 | 6 | {“printer_pdf”:”4644”, “printer_raw”:”777”, “scale_id”:”232”} |

| WORKSTATION | Testing Station | 7 | 7 | {“printer_pdf”:”screen”, “printer_raw”:”232”, “scale_id”:”0”} |

Below is a sample Workstation Definition for LOV Attribute 2:

{

"printer_pdf": "49600",

"printer_raw": "49604",

"scale_id": "5637",

"scale_name": "toledo",

"start_bin_id":"DOCK.2",

"work_zone":"ZONE-A"

}

Note

The values in LOV Attribute 2 relate to PrintNode IDs associated with each printer or scale used in the operation. If multiple scales are attached to the same workstation, a Scale Name must also be set to identify the specific scale that ShipHawk WMS should be reading. Please refer to section on PrintNode for more details on setup and usage.

Status¶

Usage:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 |

|---|---|---|---|

| STATUS | Inventory Status | ERP Internal ID for the Virtual Location associated with this Status | Internal ID for Operator Site |

Examples:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 |

|---|---|---|---|

| STATUS | GOOD | 1 | 1 |

| STATUS | HOLD | 9 | 1 |

| STATUS | DAMAGED | 12 | 1 |

Note

See Rules for attribute “availablestatus” (defaults as “GOOD”) which defines the single status considered as available to allocate inventory. All other statuses defined against inventory will be considered unavailable for standard allocation against orders.

Carrier Service¶

Usage:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 | LOV Attribute 3 | LOV Attribute 4 |

|---|---|---|---|---|---|---|

| SERVICE | Description of the Carrier Service | ShipHawk WMS ID and Sorting | Carrier’s Internal Code for this Service | Carrier ID | Carrier SCAC | Days in Transit |

Examples:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 | LOV Attribute 3 | LOV Attribute 4 |

|---|---|---|---|---|---|---|

| SERVICE | UPS Ground | 1 | 03 | UPS | UPSN | 5 |

| SERVICE | UPS Second Day Air | 2 | 02 | UPS | UPSN | 2 |

| SERVICE | UPS Next Day Air | 3 | 01 | UPS | UPSN | 1 |

| SERVICE | UPS SurePost | 4 | 93 | UPS | UPSN | 5 |

| SERVICE | FedEx Ground | 5 | FEDEX_GROUND | FEDEX | FDEG | 5 |

| SERVICE | FedEx Pri Overnight | 6 | FIRST_OVERNIGHT | FEDEX | FDEG | 1 |

| SERVICE | FedEx Std Overnight | 7 | STANDARD_OVERNIGHT | FEDEX | FDEG | 1 |

| SERVICE | FedEx 2 Day | 8 | FEDEX_2_DAY | FEDEX | FDEN | 2 |

| SERVICE | USPS Priority | 9 | Priority | USPS | USPS | 2 |

| SERVICE | USPS Parcel Select | 10 | ParcelSelect | USPS | USPS | 5 |

| SERVICE | USPS Express | 11 | Express | USPS | USPS | 5 |

| SERVICE | Asendia PMA | 12 | PMA | ASENDIA | USPS | 5 |

| SERVICE | Asendia ISAL | 13 | ISAL | ASENDIA | USPS | 5 |

| SERVICE | Asendia IPA | 14 | IPA | ASENDIA | USPS | 5 |

Note

As many or few carrier/services may be defined. If the service is received from the ERP as “Standard” and Carrier is specified, ShipHawk WMS will rate shop the best service for the shipment using that Carrier. If the Carrier is NOT specified, ShipHawk WMS will rate shop the best service for the shipment across all authorized Carriers.

Container¶

Usage:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 |

|---|---|---|---|---|

| CONTAINER | Description of the Container | Customer defined ID for the Code | Sorting Order | A JSON Object which describes this container |

Examples:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 |

|---|---|---|---|---|

| CONTAINER | A1 BOX | A1 | 1 | {“length”: 8, “width”: 5, “height”: 4, “packfactor”: 0.80, “tare”: 0.45, “id”: “5265”} |

| CONTAINER | A2 BOX | A2 | 2 | {“length”: 12, “width”: 5, “height”: 4, “packfactor”: 0.80,”tare”: 0.45, “id”: “4637”}} |

| CONTAINER | B1 BOX | B1 | 3 | {“length”: 16, “width”: 8, “height”: 6, “packfactor”: 0.85,”tare”: 0.45, “id”: “4276”}} |

| CONTAINER | M1 MEDIA PACK | M1 | 4 | {“length”: 6, “width”: 8, “height”: .5, “packfactor”: 0.90,”tare”: 0.45, “id”: “5462”}} |

| CONTAINER | M2 MEDIA PACK | M2 | 5 | {“length”: 8, “width”: 10, “height”: 1, “packfactor”: 0.90,”tare”: 0.45, “id”: “6443”}} |

Below is a sample Container Definition for LOV Attribute 2:

{

"length": 16,

"width": 12,

"height": 1,

"packfactor": 0.80,

"tare": 0.65,

"id": "52654"

}

Length, width, and height are the external dimensions of the container type. The pack factor defines the maximum cube utilization (0.0 - 1.0) for the container when considering all typical packing materials required for this container type. Tare is the empty weight of the container (used any time a weight check is used). The “ID” is optionally used to identify the container type’s internal id assigned in the ERP.

Adjustment Types¶

Usage:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 | LOV Attribute 3 | LOV Attribute 4 | LOV Attribute 5 (optional) |

|---|---|---|---|---|---|---|---|

| ADJUST | Description of the Adjustment Type | Sorting Order | ERP Internal ID for this Adjustment Type | ERP Internal ID for the Expense Account to be used | Default ERP Class Internal ID | Default Department ERP Internal ID | Used only in Location Internal ID |

Examples:

| LOV Type | Lov Description | LOV Code | LOV Attribute 1 | LOV Attribute 2 | LOV Attribute 3 | LOV Attribute 4 |

|---|---|---|---|---|---|---|

| ADJUST | LOST | LOST | 10 | 2345 | 3 | 4 |

| ADJUST | FOUND | FOUND | 11 | 2345 | 3 | 4 |

| ADJUST | QUALITY ASSURANCE | QA | 8 | 2567 | 3 | 4 |

| ADJUST | DAMAGED | DAMAGED | 2 | 2345 | 3 | 4 |

| ADJUST | MARKETING | MARKETING | 3 | 2789 | 4 | 5 |

| ADJUST | OTHER | OTHER | 7 | 2345 | 4 | 5 |

Item Master Setup¶