Putaway¶

The following section describes the putaway process within ShipHawk WMS.

Putaway Overview¶

ShipHawk WMS provides directed/suggested putaway based on item characteristics, current inventory status, bin availability, crossdock demand, and putaway rules. Putaway is most traditionally thought of as a post-receiving process, from dock-to-stock; however, ShipHawk WMS putaway logic can be used on any move in the warehouse. As discussed below, ShipHawk WMS putaway logic will display/suggest up to three candidate bins, and will present the current inventory for each of those suggested bins. Operators may choose any of these bins with ease, and even split the putaway across bins if desired. Putaway can direct inventory to randomly assigned bins (based on rules presented below), fixed bins, bins with like inventory, or empty bins, Putaway can control the movement of single items, or multiple items in a common container. For example, a container for a multi-item packed order awaiting shipment can be directed to a storage bin using putaway for “pack and hold” or “consolidation” business processes. In summary, ShipHawk WMS putaway can be used for directing the inventory storage of:

- New receipts

- Crossdock moves

- Rewarehousing moves

- Replenishment moves

- Pack and hold processes

Putaway Logic¶

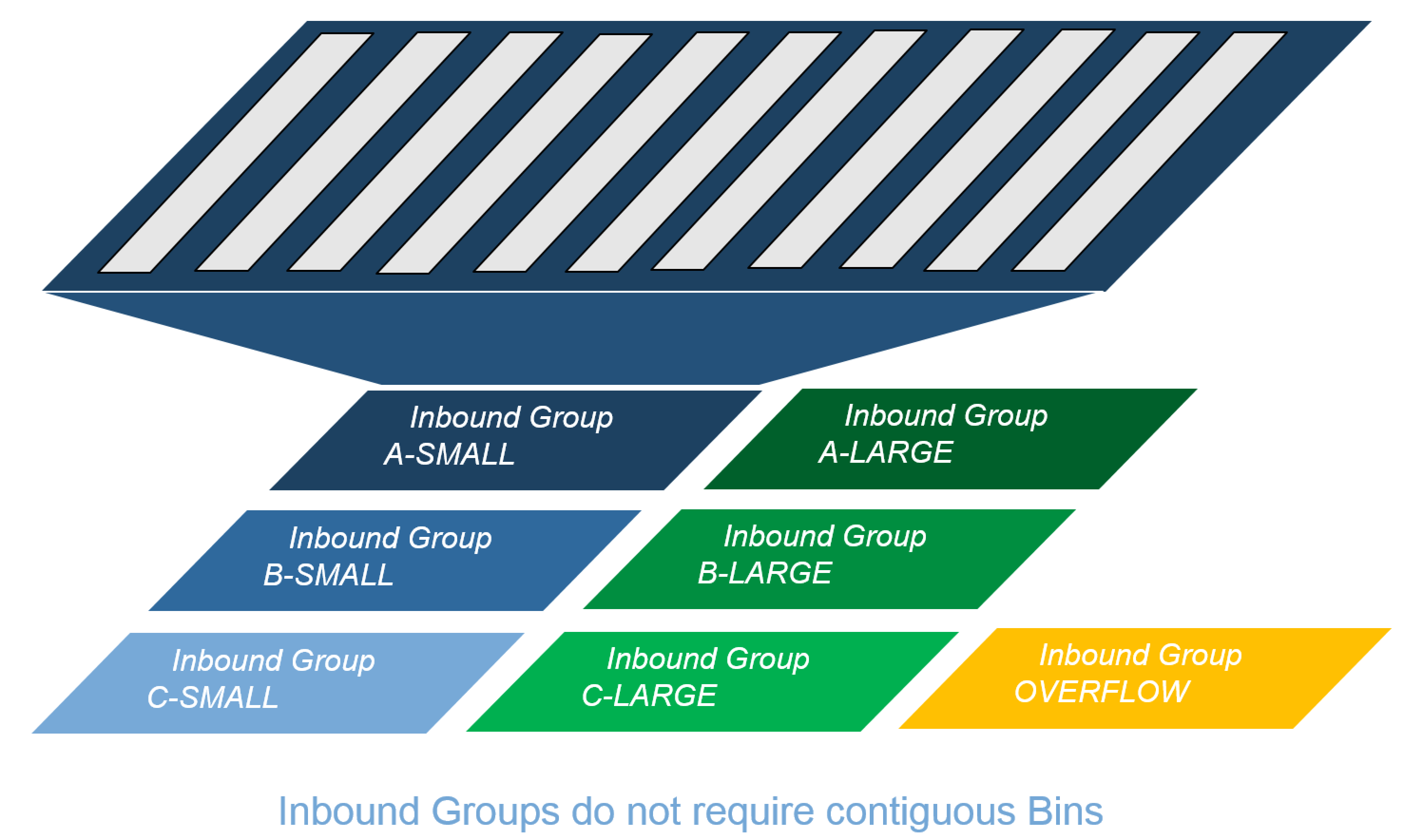

ShipHawk WMS’s putaway logic is based on the concept of “Inbound Groups” of bins.

Once all Inbound Groups are defined for physical bins, each item is assigned a Rule Set for putaway. That Rule Set will be used to direct the movement or putaway of that item from any bin (including receiving docks) to any other bin. ShipHawk WMS will retrieve this Rule Set and search, in sequenced order, across the bins for each Inbound Group defined for that Rule Set, seeking suitable bins for placement of the inventory. Each Inbound Group also has a set of related secondary rules as well, to control merging options and other best practice putaway processes.

Operations & Usage¶

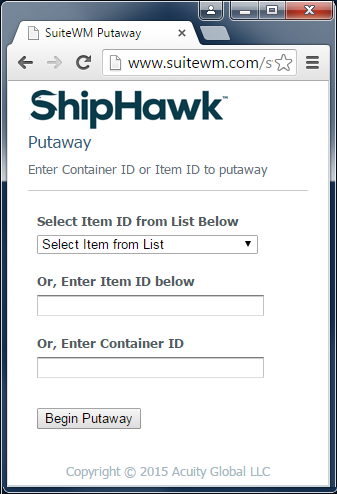

Putaway begins with the scan or entry of a Container ID or Item ID. If a Container ID is scanned, ShipHawk WMS will use the characteristics and content of that inventory load to find the appropriate Rule Set (described above) to find a suitable bin location for putaway. If an Item ID is scanned, ShipHawk WMS will look across all Containers on the receiving dock for that item, and if only one is found, will direct the putaway automatically. If multiple Container IDs are found for the item that are all candidates for putaway, ShipHawk WMS will present a list of candidate Containers to putaway that the operator may select from. Lastly, a simple drop down menu is also available, always showing the status of all candidate containers to be putaway. From this drop down, a container can be easily selected and acted upon.

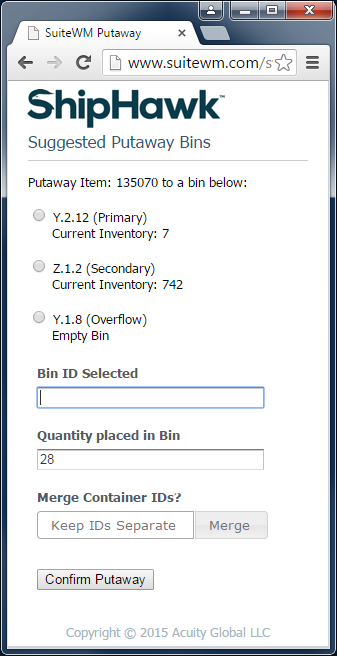

ShipHawk WMS presents the operator with several putaway options, a preferred bin based on the rules defined, a secondary bin (also based on the rules), and an empty bin candidate. These bins suggestions are all selected by ShipHawk WMS using the Rule Set that is applicable to the container.

Tip

Using Check Digits: For operations which do not yet have Bin IDs fully barcoded, or alternatively, for operations which want verify arrival at a Bin without actually scanning the actual Bin ID, ShipHawk WMS fully supports the concept of “Check Digit” bin validation. Any two or three digit numeric (or character) code randomly generated “Check Digit” can be defined for each Bin, and then printed at the bin, either as human readable, a barcode, or both. These values need not be unique, but common values should be randomly dispersed throughout the facility. Using this feature, ShipHawk WMS may direct, for example, the operator to “Travel to Bin A.10.12.4”. The barcode (or human readable value) on the bin reads “82” (a random “Check Digit” value). The operator would then either enter “82” or scan the barcode (which also captures “82”). Using this best practice, the operator in a non-barcoded warehouse can verify arrival at the bin, without actually having enter “A.10.12.4”.