Cycle Count¶

The following section describes the cycle count process within ShipHawk WMS.

Cycle Count Types¶

ShipHawk WMS supports three types of cycle counting:

- Directed Cycle Counting

- Manual Cycle counting

- Short Pick Cycle Counting

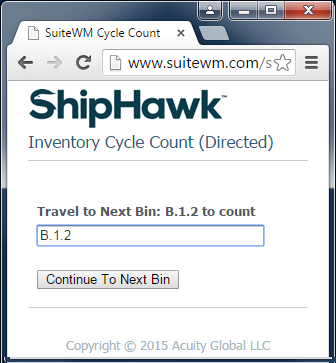

Directed Cycle Counting¶

Directed Cycle Counting will guide the operator from bin to bin, in a sequenced manner, according to the rules/filters defined, count plan requirements, and current count state of each bin. Filters can be defined by the operator upon initiating the feature to drive a multitude of options, including:

- Specific bin, aisle, or area of the warehouse

- Specific Item or Item Family

- Bin inventory threshold

- Specific count plan

- Recount threshold

- Bins with no activity

- Empty or non-empty bins

Tip

Using the “empty bin” or “low inventory” count filters, an operation can quickly verify the count for all low inventory and/or empty bins in the warehouse. This is tremendous benefit for two reasons: (1) it is extremely easy and fast to verify a low inventory count or empty bin, and (2) low inventory bins are the most vulnerable to an unexpected stock out based on an inventory inaccuracy.

Each of these filters/options is described in more detail below.

If any count varies from what is expected, the count will immediately show up on the Resolve Count Discrepancies page (discussed below) for an authorized operator to review and accept, or recount.

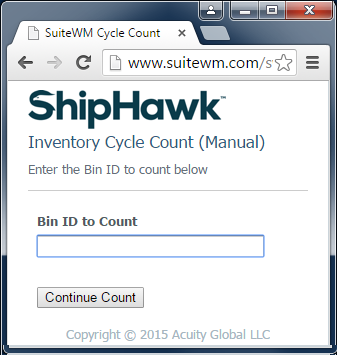

Manual Cycle Counting¶

Manual Cycle Counting allows to operator to simply scan/enter a bin and perform a count. ShipHawk WMS will not direct the operator to a bin, rather, the operator simply chooses the bin to count. No preparation is required at all, simply scan a Bin, scan an Item, enter a count, and move on. If the count varies from what is expected, the count will immediately show up on the Resolve Count Discrepancies page (discussed below) for an authorized operator to review and accept or recount.

Short Pick Counting¶

Anytime an inventory discrepancy is detected, a cycle count task will be recorded into the resolve cycle counting queue and scheduled to the next available operator to review based on the rules established.

Note

It should be noted that if a operator records a “short pick” (not enough inventory to satisfy the requested quantity to pick or move), a cycle count is “technically” recorded a count of 0 (zero), since, by definition, the pick would not be “short” if there was enough inventory in the bin to satisfy that pick.

Operations & Usage¶

The ShipHawk WMS Count Rules page allows operator to set “filters” on the count tour.

ShipHawk WMS will direct the operator from bin to bin based on the rules established my the business and the filters defined by the operator.

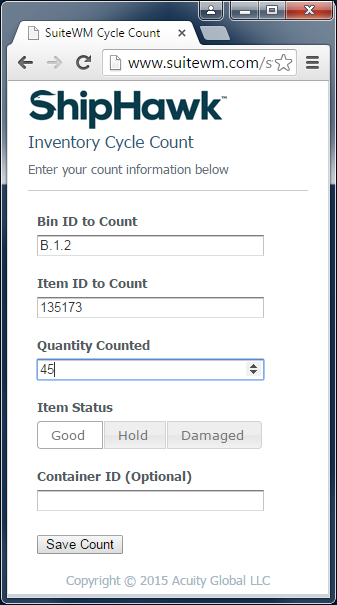

Once the operator can scan verified arrival at the bin, the operator will begin to scan any item(s) in that bin. A convenient drop down menu is available to display the items (only) expected to be counted in that bin. Quantities will never be displayed to an operator.

Once bin and item are captured, the operator is expected to enter a count. A count of 0 is allowed. An operator may also indicate that the Bin is empty.

Once the count quantity is captured, the operator is either directed to the next bin, or has the option to stay at the current bin if there are more items to count.

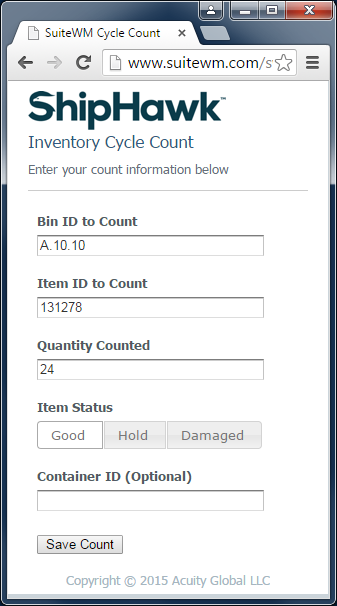

Manual counting is also supported by ShipHawk WMS. Using this feature, an operator simply scans a bin.

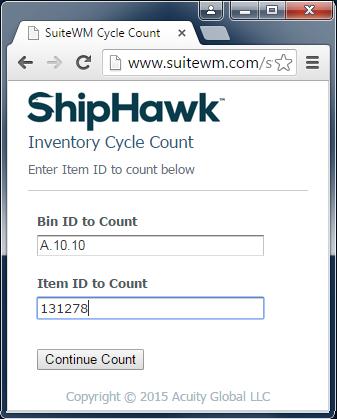

Once the bin is scanned, the operator will scan an item in that bin.

Finally, the operator will enter the quantity for that item in the bin being counted.

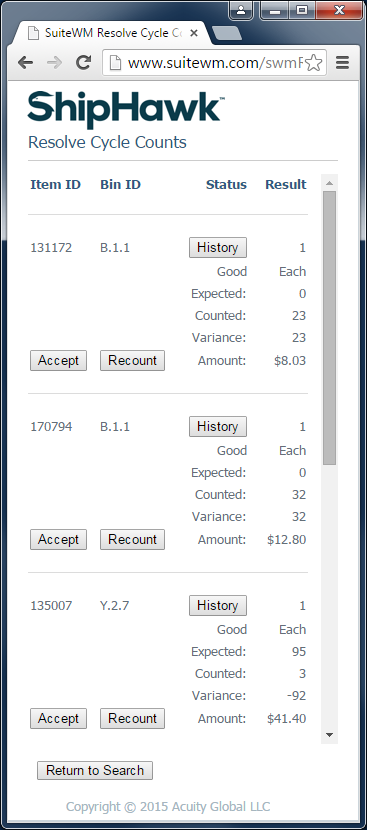

Authorized operators will be able to review all discrepant counts using the Resolve Count page. This process begins by entering filters to drill down into the most relevant data first. These filters are shown below.

Upon entering the requisite filters, all discrepant counts matching those filters will be displayed. The operator can review each count, including the history each each recount, results, and trend charts of variance. If the operator is satisfied that the count is accurate, it can be “accepted”. This immediately creates an Inventory Adjustment in the ERP (NetSuite). However, if the variance is high, and the history of counts at this bin is inconsistent or non-existent, the operator may request to have the bin recounted.

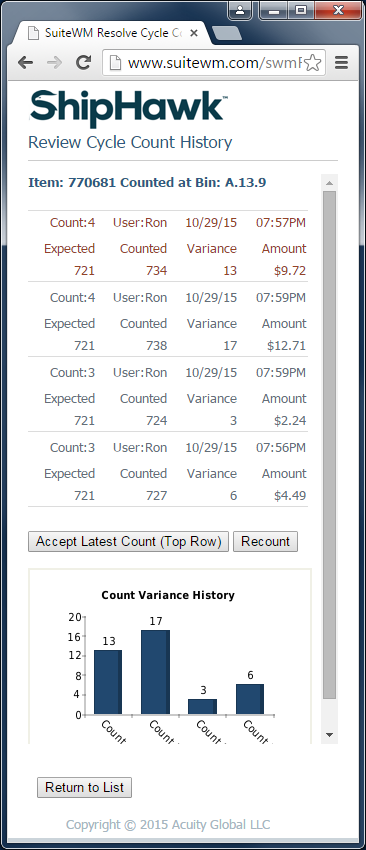

Below is an example of the Count History page which visually displays a variance bar chart over time (counts performed).

Tip

The information on this page provides valuable insight to the operator on whether to accept the current count (if no variance exists in counts) or to recount (if high variance exists between counts).

At any time, an authorized operator can view the Cycle Count result dashboard page, which will highlight the accuracy of counting by units and by bin, based on the filters defined.