Introduction¶

This section will introduce you to the basics of using the ShipHawk WMS Warehouse Management System on your mobile or desktop device.

ShipHawk WMS is an advanced Warehouse Management System solution, built and maintained by ShipHawk, to complement NetSuite (and other ERPs). It offers mid-market ease-of-use while supporting tier 1 best practices. Based on decades of hands-on domain experience and system development with warehouse management systems, ShipHawk has engineered ShipHawk WMS to deal with “real world” warehousing operations, optimizations, and exceptions. ShipHawk WMS is a high performance, easy-to-use, and reliable solution to provide best practices in receiving, putaway, move/replenishment, wave planning and optimization, picking, packing, shipping, cycle counting and more.

The ShipHawk WMS User Experience (UX) is 100% web-based and will run on virtually any mobile and fixed device that supports the WebKit- or Chromium-based browser engine, including but not limited to Firefox, Chrome, Safari, Edge, Opera, or Silk. If operating ShipHawk WMS on a mobile device, that device must be running a recent version either Google Android, Amazon Fire OS, or Apple iOS. You may also run ShipHawk WMS on virtually any modern-day desktop or tablet operating system, using one of the browsers noted above.

Note

ShipHawk WMS was designed to run a “paperless” warehouse operation using mobile devices and Barcode Scanning technology; however, ShipHawk WMS can be operated using paper-driven processes and without barcoded items, if desired or required.

ShipHawk WMS is compatible with touch screen devices, barcode scanners (acting as keyboard wedges, either wired or wireless), and traditional keyboards (soft or hard). The most common device deployed for using ShipHawk WMS in a warehouse is a Motorola TC70 Mobile Computer; however, some customers have simply chosen to deploy low-cost consumer-grade tablets with wireless scanners, typically costing substantially less. Regardless of the device, ShipHawk WMS offers a consistent, easy-to-use, intuitive user experience.

ShipHawk WMS can be deployed to the cloud or on premise in a customer’s environment. See our Technology section for details on the technologies employed. ShipHawk WMS is compatible with all major cloud services such as AWS and Azure.

Summary of Capabilities¶

Receive

ShipHawk WMS provides a unified user experience to easily and fluidly receive inventory into the warehouse, whether the expected receipt is sourced from a Purchase Order (PO), Transfer Order (TO), Return Authorization (RA), or Advanced Shipping Notice (ASN).

Putaway

ShipHawk WMS provides directed/suggested putaway of inventory receipts based on item characteristics, current inventory status, bin availability, crossdock demand, and putaway rules. Putaway can direct inventory to randomly assigned bins (rule based), fixed bins, bins with like inventory, or empty bins.

Replenish

ShipHawk WMS offers several different ways to execute inventory moves throughout the warehouse. Manual moves, or system-directed moves and replenishments will be directed by ShipHawk WMS as inventory is required for different needs throughout the operation.

Optimize

ShipHawk WMS embeds advanced optimization techniques to rapidly identify the best orders to group together for wave management. Optimization techniques consider the affinity of items, line counts, unit counts, packing requirements, travel paths, shipping, priority and more to assign groups of tasks/orders into the most efficient pick batches possible.

Pick

ShipHawk WMS supports best practice, advanced paperless picking methods including Cluster (group of orders picked to a cart), Batch (group of common orders pick together), Super Batch (group of batches picked to a cart), Wave (group of orders in a wave all picked together), Consolidation (group of orders for a common customer shipped together), and of course, Order picking.

Pack

ShipHawk WMS packing features allow the operation to perform a 100% scan-verified inspection of picked orders (if desired), as well as define, document, label, and prepare containers/packages for shipment. Value added services and specialized labeling are also supported through ShipHawk WMS. SSCC18 carton labels for retal compliance can also be generated during packing or shipping operations.

Ship

ShipHawk WMS provides real time shipment manifesting processes to produce ship labels and supporting documentation for UPS®, FEDEX®, USPS®, as well as other parcel and freight carriers. International consolidation shipping services offered by Global-e and Passport are also available in ShipHawk WMS. A VICS BOL is produced for all LTL shipments. UPS®, FEDEX®, USPS® trademarks are property of their respective owners.

Count

ShipHawk WMS Cycle Counting is a best practice tool to keep inventory perpetually accurate in bins across the warehouse. ShipHawk WMS automatically directs operators to count bins/items based on rules defined by the operation. ShipHawk WMS also provides sophisticated count reconciliation tools to review variances and decide the disposition of each count. Counts may be directed, manually initiated, or triggered by certain events such as a short pick.

Search

ShipHawk WMS provides lightning-fast search and reporting of inventory levels by bin, item, and/or container. In addition, order status, complete history, task details, shipment tracking IDs, and order attributes are available in a flexible and intuitive manner. With authorization, documents can be reprinted or regenerated, and orders can be reset or even cancelled if required at any time.

KPIs

ShipHawk WMS captures and displays real time results for 36 best practice Key Performance Indicators (KPIs) across all operation. These KPIs can be visualized in charts and graphs, or presented in tubular form, all in real time. Performance trends over time and snapshots of current activities are all available by user, date and location.

Note

While ShipHawk WMS is a comprehensive Warehouse Management System solution built based on decades of best practice experience, not all ShipHawk WMS features and functions need to be implemented at once to add value to your business. In fact, many customers are simply seeking an improved Cycle Count tool in the warehouse. Some wish to begin using Barcode Scanning in one or many of their departments. Others may wish to only implement an optimized Wave/Pick operation. Many may use the powerful Document Processing engine or EDI Processing engine for Integrating with a 3PL. Regardless of the need, the fact is that ShipHawk WMS is highly modular, scalable, and dynamic solution that can be adapted to many different needs and/or configuration requirements. ShipHawk stands ready to discuss your challenges in the warehouse, and suggest ways that ShipHawk WMS can add value to your enterprise.

Getting Started¶

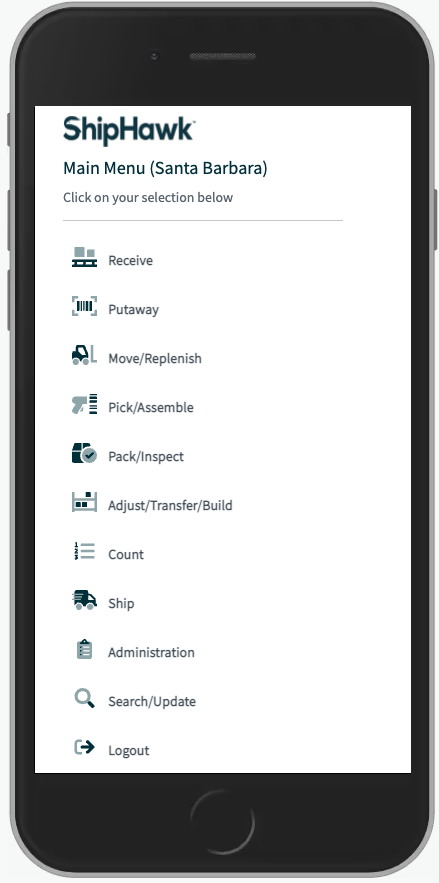

The following sections present the basic operations of accessing ShipHawk WMS and overall navigation.

Login¶

ShipHawk WMS is accessed using a web browser and a URL. Issuing that URL within your browser will direct you to the ShipHawk WMS Login Page. Trying to access any other page in ShipHawk WMS without an authenticated session will always redirect you to the ShipHawk WMS Login Page.

Note that when logging in, you can either use the “Use my default” option for Location, Division, Role, or Workstation, or you can select a specific value. All user credentials are defined in the ERP (NetSuite) using an Employee table. This table defines the credentials (encrypted) and default values for each user. If a user picks specific values for Location, Division, Role, and Workstation, that user must be authorized to use each of those settings. However, since it is not known which user will login next, all settings are always presented in the Login page. For example, You cannot login as an Administrator if you do not have Administrator role defined on your ShipHawk WMS Employee record in the ERP (NetSuite), even if you entered a valid username and password. You must always enter a valid username, password, role, location, division, and workstation to gain access to ShipHawk WMS.

Once you successfully login, a summary of your settings will be presented. This includes the location, division, workstation, and role you will be operating under while your session is active.

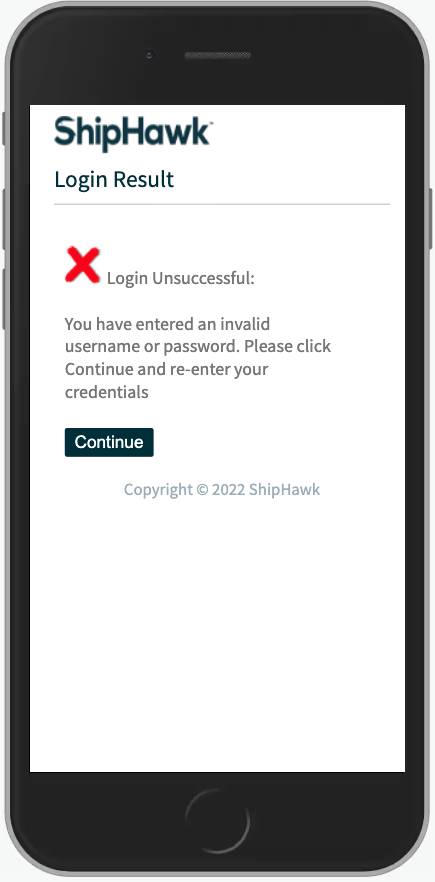

If your login is unsuccessful, ShipHawk WMS will display this failure and ask you to attempt your login again.

Logout¶

When you have completed you activities in ShipHawk WMS, simply select Logout and ShipHawk WMS will end your session and prepare the terminal for the next user to use.

Barcode Scanning¶

ShipHawk WMS is designed and developed from the ground up to support barcode scanning of data, whether it is an item’s UPC/EAN/GTIN, a bin location’s ID, or carton’s SSCC-18 label, or any other possible barcode presented, 1D or 2D. In fact, the entire user experience is engineered around the methodology of “scan-and-go” meaning that any element in the system can be scanned by an operator (rather than key entered), and ShipHawk WMS will automatically (upon data validation) move to the next entry element, while providing the relevant context of previous data entered for the task at hand.

In addition, ShipHawk WMS is engineered to track inventory using the best-practice concept of “License Plates” or “Container IDs”. These (traditionally barcoded) IDs stay with the inventory from initial receipt throughout the entire lifecycle of that inventory.

Tip

ShipHawk WMS is also sensitive to the fact that many different barcoded values can lead to the same identifier in the database, whether it’s an item or bin. For example, if an operator, scans a UPC/EAN, a Vendor’s Code, an ISBN, an NDC, or other item identifier, ShipHawk WMS will look up this value and find the proper item to validate against. Of course, these alternate values must be defined in NetSuite or the ERP Item Master. In addition, if the scan results in multiple items being found, and ShipHawk WMS must know exact which item is being handled (at receiving for example), ShipHawk WMS will provide that list to the operator for further refinement. Likewise, ShipHawk WMS allows the operator to scan a bin identifier or enter/scan a check digit to validate arrival at a bin.

NetSuite Integration¶

While ShipHawk WMS is fully capable of working with most ERP solutions, ShipHawk WMS has been specifically engineered to operate seamlessly with the NetSuite solution. ShipHawk has been working with the NetSuite platform since 2007 to develop and refine a real-time, high-performance, reliable integration with NetSuite that creates a unified experience for the operation.

Our NetSuite Integration methodology extends far beyond the technology and/or APIs used; it is an integration that builds on decades of “order-to-cash” and “purchase-to-payment” experiences and “best practices” in the enterprise as they specifically relate to the warehouse operations.

- Item Fulfillments are processed in the warehouse whether sourced from NetSuite Sales Orders, Transfers Orders, or Return to Vendor documents.

- Item Receipts are captured in the warehouse and posted to their appropriate Inbound Shipment (IS), Purchase Order, Transfer Order, or Return Authorization documents maintained by NetSuite. ShipHawk WMS accepts ASNs (EDI 856, for example) from your vendors, permitting efficient receiving across multiple Purchase Orders in the same container.

- Item Fulfillment status is updated as the order is processed through the warehouse, culminating in Shipped status. Standard (and custom) data elements and tables are populated to support the subsequent generation of EDIs through the use of SPS Commerce or Boomi integration tools.

- Changes, cancellations, and exception conditions are carefully synchronized in real time, as required, to keep the business always moving forward.

- Synchronized bin-level and site-level inventory is always visible in ShipHawk WMS and NetSuite, as are all task details and history for all activities completed in the warehouse.

- All Item Master data and rules which drive the warehousing operation are maintained in NetSuite and synchronized with ShipHawk WMS on an ongoing basis.

ShipHawk WMS is simply an extension to NetSuite operations, but tailored and tuned to the specific needs of a warehouse operation. Technical details of this integration can be found in the NetSuite Integration section of this guide.