Streamlined Receiving, Putaway,

and Cross-Docking

Let's Talk!Optimize Placement of Inventory in the Warehouse

Optimizing receiving and the placement of inventory is always one of the top reasons a business looks to a warehouse management system (WMS). While it may seem straightforward, placement is often the cause of wasted time traveling throughout the warehouse and inventory shortages for orders that have to go out within a specific time frame. In fact, 60% of a warehouse worker’s time is often spent picking orders as a result of this. ShipHawk WMS offers solutions for the initial stages of products arriving in the warehouse including:

- Intuitive receiving

- Directed-putaway

- Effortless cross-docking

Learn more about ShipHawk WMS→

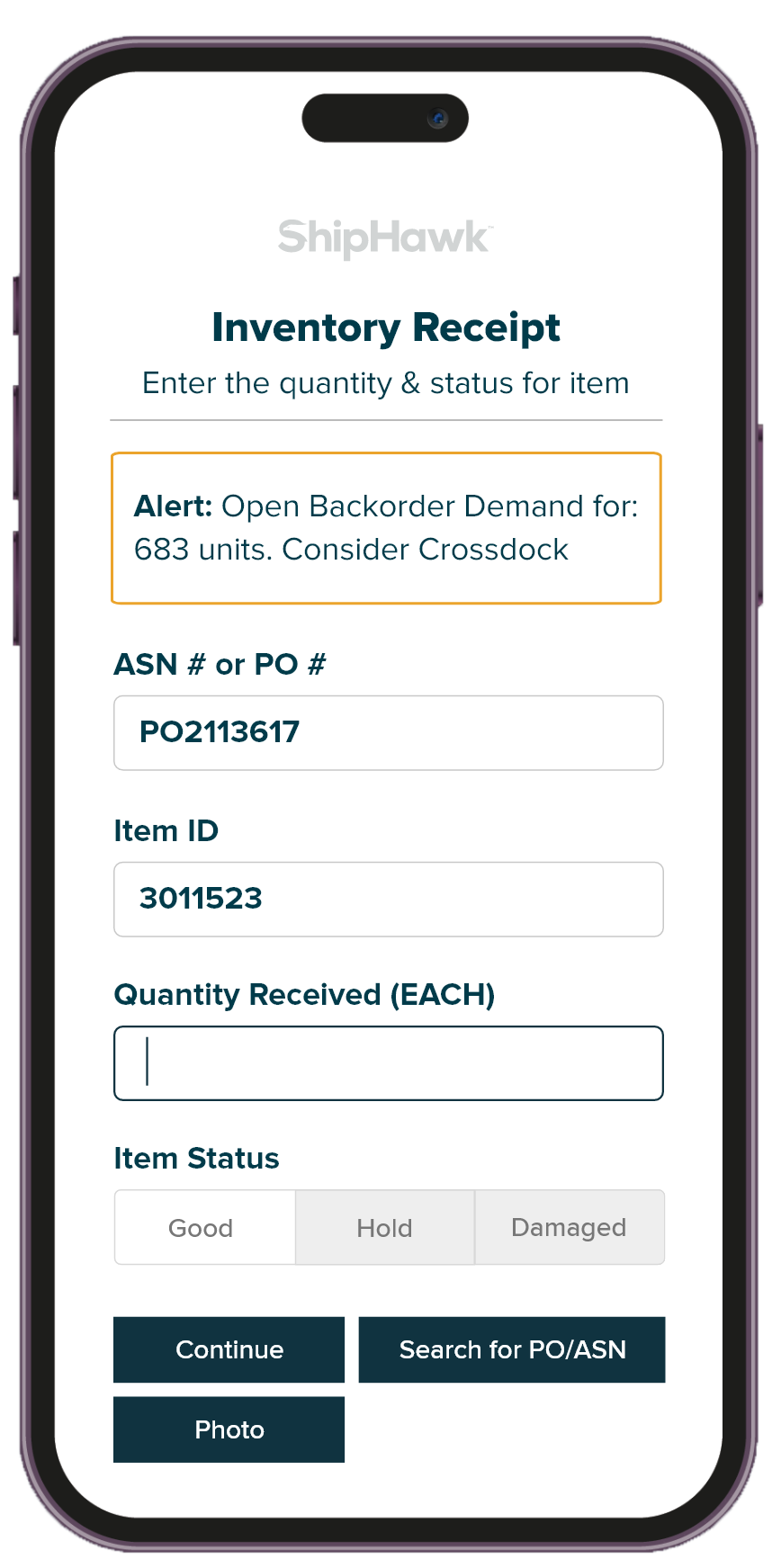

Streamlined and Intuitive Receiving

ShipHawk WMS’s receiving functionality enables you to streamline the receival of goods coming into the warehouse, ensuring that the materials are what was ordered and meet quality standards, and then move the items so they can be put away or sent directly out of the warehouse again if allocated to a backorder or shipment in progress.

ShipHawk WMS supports receiving types including:

- Purchase Orders

- Transfer Orders

- Return Authorization

- Inbound Shipments and ASNs (Advanced Shipping Notifications)

System-Directed Putaway

ShipHawk WMS’s system-directed putaway allows the system to determine where items should be placed most efficiently, removing the need to rely on tribal knowledge in the warehouse and avoiding long training times by setting up rules to determine the optimal putaway location for items.

The system looks at which items in your warehouse are moving the fastest and slowest based on inventory turns and determines the best place for each item. The fast movers are recommended to be placed as close to the picking station as possible to speed up pick efficiency. Additionally, putaway can also be determined by type like eCommerce, wholesale distribution, or even special products that should be reserved for VIPs or collector’s editions.

Combining License Plate Best-Practices with Directed Putaway

ShipHawk uses license plating, also known as container IDs, to offer real-time tracking of inventory at all times, supporting industry best practices to allow for easy movement of goods with one simple scan. When it comes to putaway, the user will scan the license plate to see the directed putaway location. After scanning the license plate, the system will suggest a primary bin, a secondary bin if the primary is full, and overflow bins. ShipHawk WMS looks at all bin locations with the same item and assigns primary and secondary bins based on bin proximity to expedite pick time.

ShipHawk WMS also allows you to see what’s been put away each day with a daily activity report. By reviewing your team’s putaway activity, you can ensure employees are getting their tasks done and track user productivity for areas of improvement.